Cutting the Cord

You could buy a shorter cord to supplement the longer version that came with the RV — or you can cut it in half and add the appropriate ends to make two cords out of one.

Replaceable plugs and receptacles are readily available; we chose the ones offered by Camco and found the pair on Amazon for just under $40. Search for “Camco Powergrip RV 50 amp plug and receptacle” and you’ll find individual listings. While there are numerous plugs and receptacles out there, the Camco products meet National Electrical Manufacturers Association (NEMA) standards, which are American National Standards Institute (ANSI) accredited. ANSI 1192 standards are the ones adopted by the Recreation Vehicle Industry Association (RVIA) for construction compliance.

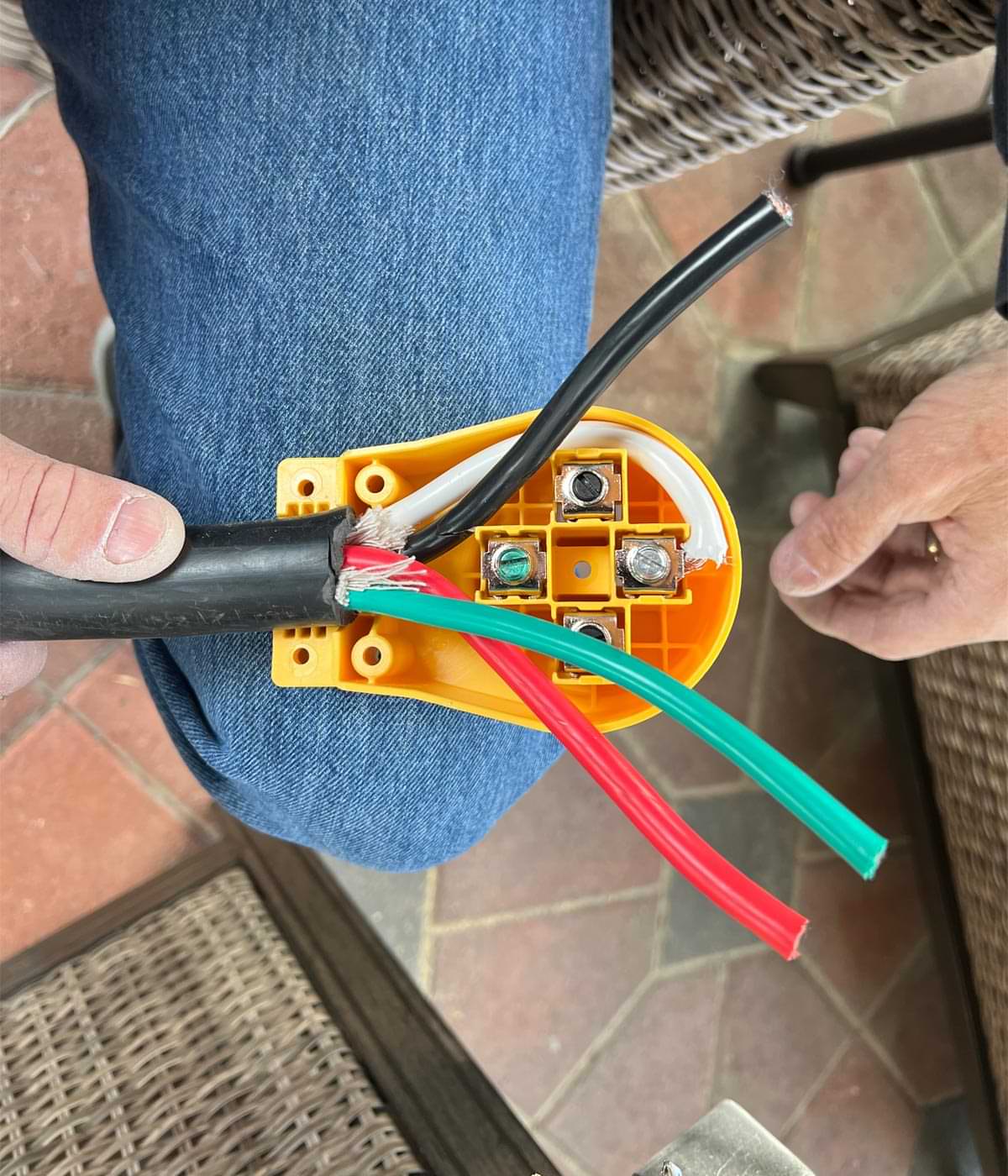

Once the cord is cut you’ll need to match the right ends, with the plug attached to the other end of the cut cord still with the RV connector. The other length of cord gets the receptacle — the plan being to be able to connect the two new ends when the entire 30 feet are needed. Wiring the two ends is not complicated, but the wires are big and bulky and require proper orientation when connecting to the terminals, which is clearly described in the instructions.

The best tool for connecting the plug and receptacle is a heavy-gauge wire strippers; since most of us won’t have this, a decent utility knife works fine. Diagonal cutters will also come in handy for removing the fabric-type material between each wire when wrapped in the casing.

Carefully measure the wires as they relate to the terminal locations inside the plug and receptacle and cut back the insulation with the utility knife. Start with longest wire first, paying close attention to where the cable with be secured in the strain relief clamp. Make sure none of the wire strands touch each other. Figure on a couple hours to get the job done.

The plug end must be connected to the cable with the fitting for attaching to the RV receptacle on the other end.

It’s possible that connecting the plug and receptacle when the entire cable is needed will result in a tight fit. Each end has a molded handle, which provides a good grip when pulling apart but might require that two people to play tug-of-war at first. Consider adding a thin coating of dielectric grease to the prongs and treat the wire connections inside the plug and receptacle with a corrosion inhibitor like DeoxIT contact treatment from Caig Laboratories (caig.com).

Already a Subscriber? Click here for Access to the Full Issues.