Under Pressure

Most of us don’t give a lot of thought to our tires. Other than periodically checking them for the correct inflation pressure and giving them a quick scrub when washing our vehicles, tires are basically taken for granted. So long as they have adequate tread and aren’t outside the recognized “aging window” they are just expected to perform.

When they don’t, however, all sorts of things can happen — none of them good. Air carries the load, and if there’s a problem that the driver isn’t aware of, it can be catastrophic. Most tire problems can be traced to low air pressure, which affects RV tires differently than those on the family car. Unlike a passenger car tire — where the contact patch between the tire and the road gets wider as the air pressure is reduced — travel trailer tires elongate because of the heavy sidewalls needed to support the load. A longer contact patch creates more friction — and that creates more heat. And once the tires get hot enough for the vulcanization (tire construction) process to start breaking down, the tire can suffer from a blowout.

The simple solution is to oversee what’s going on with vehicle tires using an aftermarket tire-pressure-monitoring system (TPMS). Available from a number of companies, these systems usually include sensors threaded onto each tire’s valve stem that send signals to a display monitor mounted inside the tow vehicle (or on the dash of a motorhome); most of them provide continuous monitoring of both air pressure and temperature. Should either reading exceed low or high limits entered into the monitor, lights and/or audible alarms warn the driver — who can then pull off the highway before calamity ensues.

We followed the installation of a TPMS manufactured by Truck System Technologies (tsttruck.com), a company that specializes in TPMS for RV use. TST’s externally mounted sensors are available in a number of styles, including cap sensors (which require removal to inflate the tire), flow-through units (which allow tire inflation through the attached sensor) and a hybrid sensor that’s approved for salt-water immersion. Each sensor incorporates a coin-style battery that’s good for between 12 and 18 months.

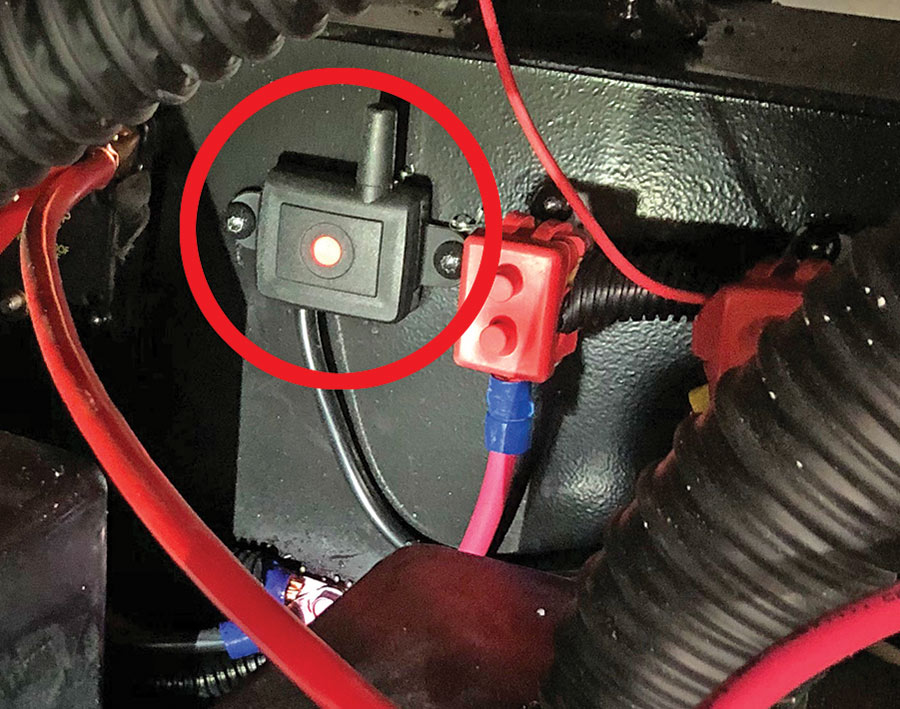

Installing a TST aftermarket kit is a straightforward affair that only requires about 20 minutes to complete. The toughest part may be mounting the signal repeater near a 12-volt DC power source. The short wiring harness includes terminal ring connectors to place on the positive and negative battery terminals, while the small waterproof repeater housing can be attached to a wall inside the battery housing location using the supplied hook-and-loop pad or by screwing it in place.

Kits are priced according to the number of sensors included and range from the high $200 range for a two-sensor kit to about double that for an eight-sensor package. All kits include the sensors, installation wrenches, signal repeater and display monitor with dash and window mounts and, to power and charge the monitor’s lithium-ion battery, an adapter with micro-USB cord that plugs into the dash power port. All kits also include extra hardware used during installation and extra O-rings used when opening the sensor to replace the battery. Additional sensors can be purchased separately.

Already a Subscriber? Click here for Access to the Full Issues.