A Cooling Trend

It is common knowledge that electronic devices do not bode well in a high-temperature environment; many even have internal fans to prevent overheating and possible failure. When components like a DVD player, digital video recorder, satellite receiver and stereo systems are stuffed into a cabinet with a glass or wood door that is closed all the time, the temperatures inside can soar to unacceptable levels. Obviously, you can open the door while any of the components are in use, but most people just leave them closed because modern remote controls will function right through a glass window or door. Leaving a door open is also a head-banging hazard for taller occupants.

There are some RV manufacturers that install a black-painted aluminum screen material in lieu of glass or wood — which looks nice and allows for proper air circulation around the components — but in the case of my fifth wheel, I had to contend with glass surrounded by a hardwood frame. Kicking myself for not figuring out a solution sooner, I started searching for some type of decorative aluminum screen material that looks nice (and preferably painted black) to replace the glass. I quickly found aluminum screen material typically used to protect debris from entering engine compartments through front grilles on Amazon (just search for “AGGAuto Universal 40” x 13” Car Grill Mesh). And, as a bonus, it’s already painted black.

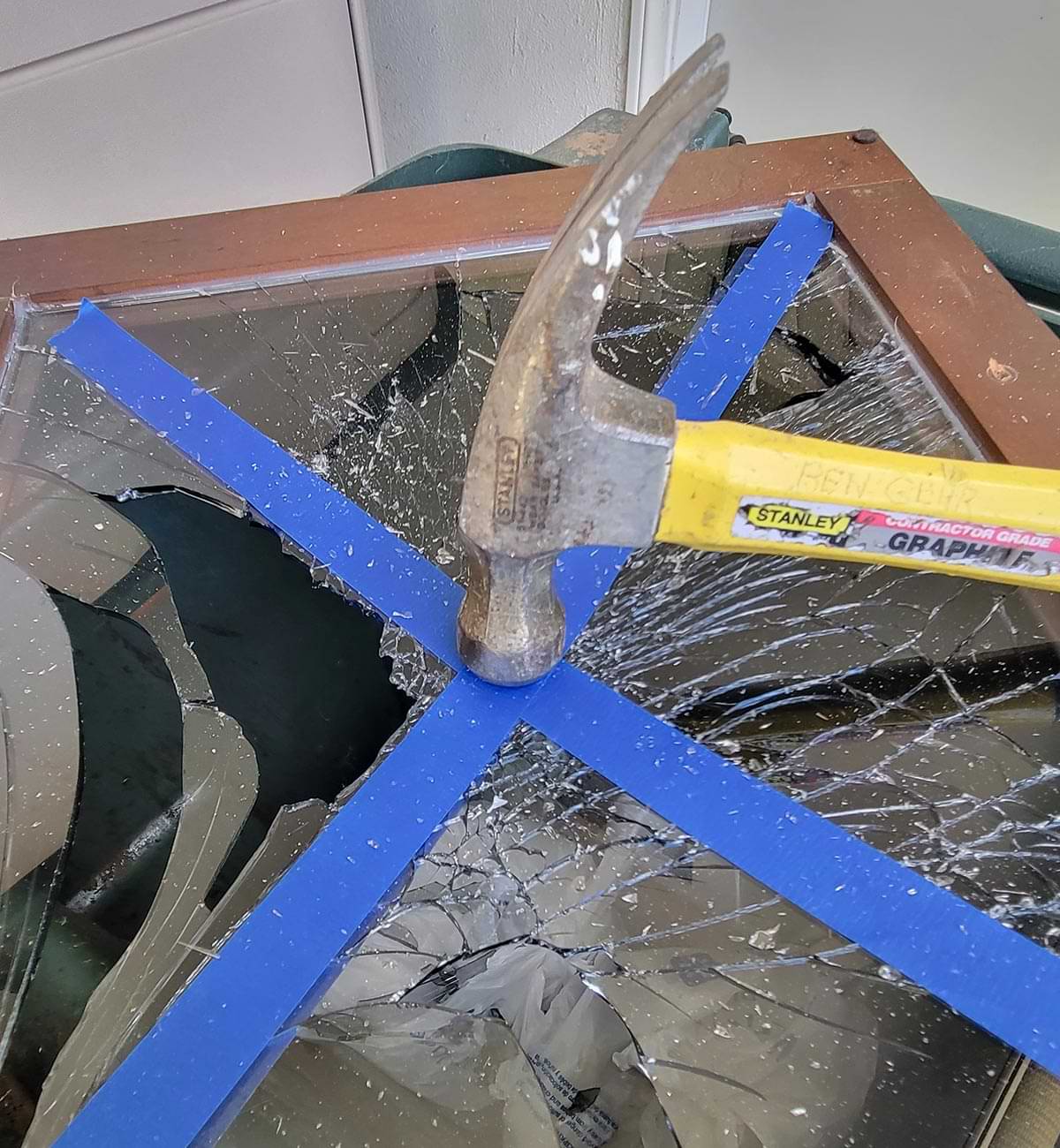

To install it, I removed the cabinet door and set it on a table (with a towel under it to prevent the wood from being damaged). The next step was to remove the handle so that the door would sit flat for installation of the screen material. As I contemplated how to get rid of the glass safely, I decided to run a utility blade around the glass to see if it would come loose — and, of course, it did not. Large beads of silicone rubber applied at the factory all the way around the glass got under it as well, gluing the glass in place. My only choice was to take a hammer to the glass, which was done while wearing safety glasses, heavy-duty gloves and an apron. I covered the glass with masking tape to contain the broken pieces, which worked well; using a healthy amount of tape will allow the glass to come out in almost one piece.

The factory applied a copious amount of silicone sealant to hold the glass in place. This silicone was carefully sliced with a razor knife. Ultimately, however, the sealant that seeped under the glass prevented the glass from popping out of the frame.

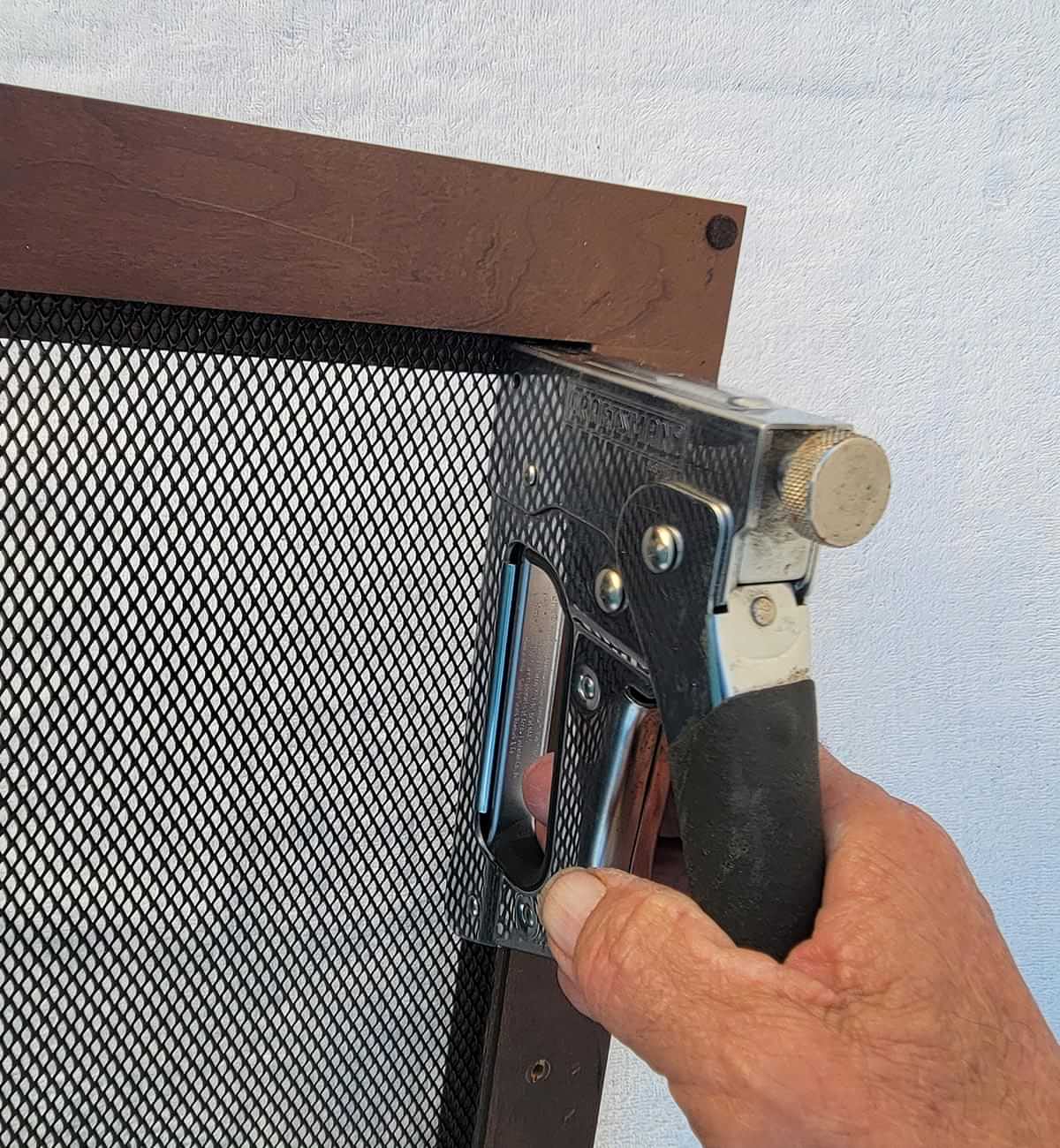

I then set the door on the aforementioned towel and table and unrolled the aluminum screen material to establish the cut size. You’ll also need to give the screen some time to stay flat after having been rolled up for packaging. Unable to mark the black screen with a felt pen, I used masking tape while setting the screen into one corner and taping in both directions. Tin snips were used to cut along the outside of the masking tape and, voila! — the screen was ready to install.

The door frame had a pretty good size lip on the inside, which allowed me to staple the screen material on all four sides; be sure to use ¼-inch staples in your gun to prevent going through the other side of the frame. Fortunately, the wood was soft enough so that the staples provided a tight fit. I put the handle back on and installed the door on the hinges that were still attached to the cabinet frame and shut the door. Mission accomplished.

Already a Subscriber? Click here for Access to the Full Issues.