Furnace on the Fritz?

Understanding the top 10 reasons why furnaces fail — and how to rectify them — will help keep your interior toasty warm during colder weather

It’s not possible to have an effective HVAC system without a source of heat. Murphy’s Law suggests that a furnace will only fail when it’s needed the most. Keeping an eye on internal components and knowing what to look for when a furnace fails — or becomes erratic — can make a big difference in whether you’ll be shivering inside a blanket or enjoying the interior space in comfort. The following applies to typical furnaces found in RVs. (Hydronic and Truma models are not covered here.)

1. LP-gas Pressure

Inadequate gas pressure will cause short cycling or a faulty ignition. Test the system for proper LP-gas pressure using a manometer (most people use a dial manometer), which should be 11 inches water column with all the appliances off. While testing the gas pressure, start the furnace ignition procedure to verify that the pressure does not completely drop out, which will indicate that the pressure regulator is defective and needs to be replaced. It’s a good idea to replace the regulator every five years, regardless of whether or not it’s working.

If you find yourself far from a service center and do not have access to a manometer, a quick way of checking for a drop in gas pressure is to ignite the burners on your stove and turn the furnace on; if the burner flames drop considerably in size or completely go out, the pressure regulator is likely defective.

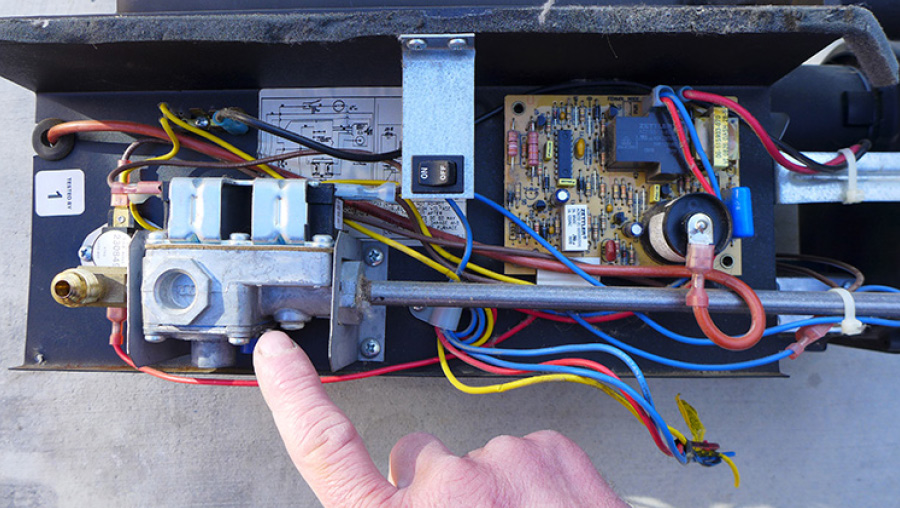

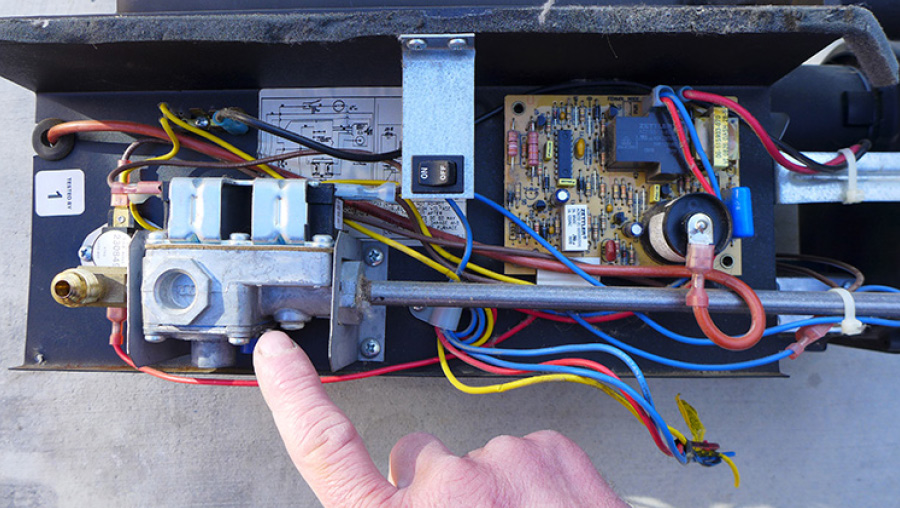

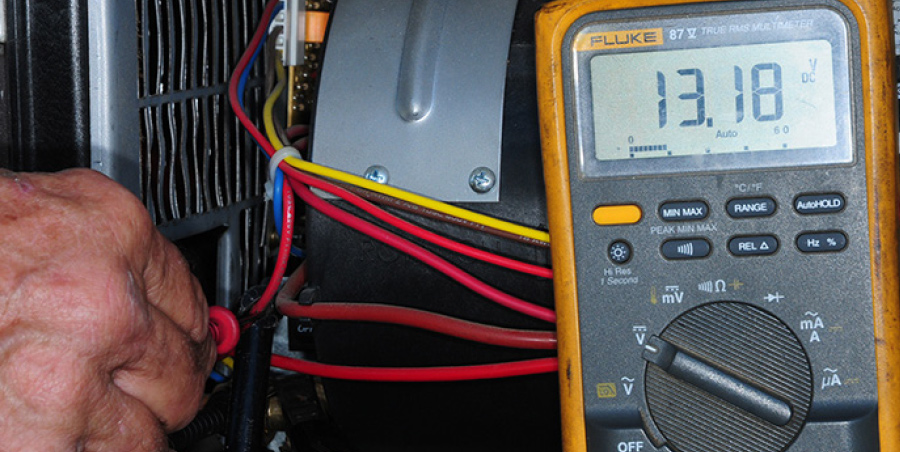

Inadequate LP-gas pressure is one of the more common maladies affecting furnace performance. Pressure should be checked if you suspect a problem with ignition; a dial manometer is the most convenient tool for checking LP-gas pressure — and regulator integrity.

This is a typical gas valve used in most older furnaces, especially Suburban models. There is a tap at the bottom of the valve allowing you to diagnose low pressure problems with a manometer.

2. Home Sweet Home — for Bugs

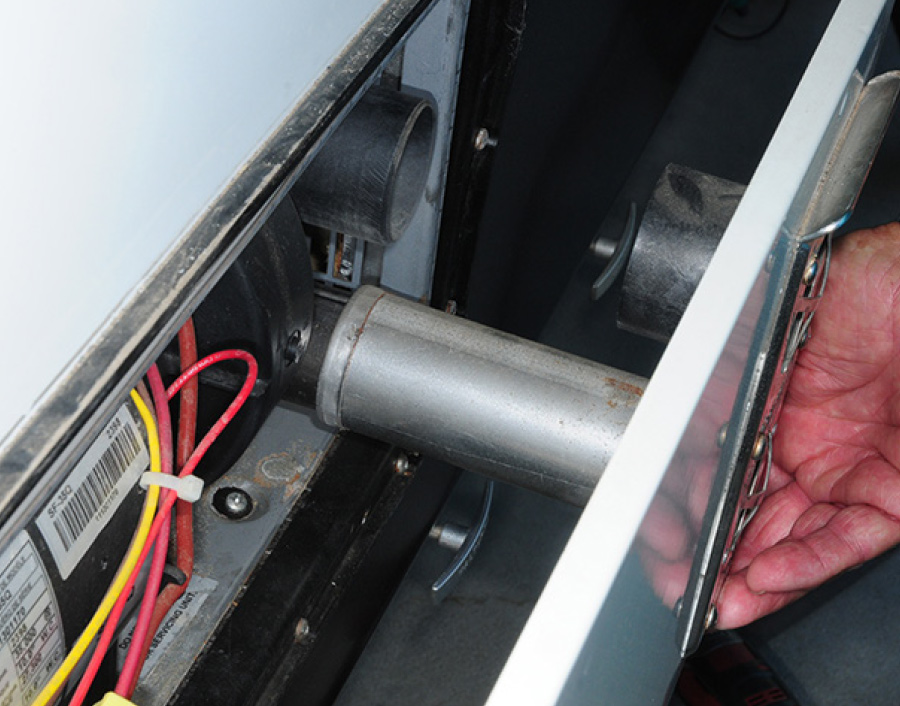

Mud daubers love the smell of propane and will nest in the intake or discharge pipes, creating a blockage. (Of course, debris can also cause a similar problem.) Using a bright flashlight, look into both pipes to detect any blockage. If the blockage is deep into the system — normally a problem caused by a mud dauber nest attached a blower wheel — you will not be able to see an obstruction from the outside. If you suspect there is a mud dauber nest inside the blower wheel, it will be necessary to remove the furnace and dismantle the blower assembly.

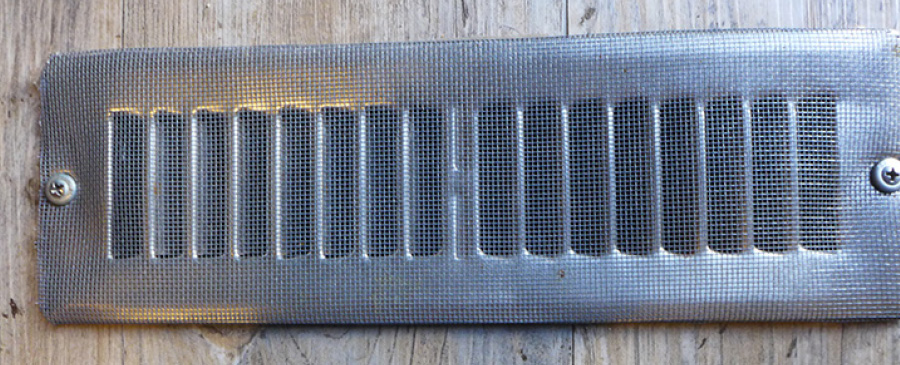

Another possible blockage could be traced to bug screens attached to the outside of the furnace at the intake and discharge ports. Manufacturers do not recommend this as it can impede air intake and discharge if the screens are allowed to plug up. If you insist on using these screens, make it a point to inspect the surface for blockage on a regular basis.

Use a bright flashlight to inspect the intake and exhaust tubes for insects and other debris. These obstructions can be cleared with a wire hanger after bending a makeshift hook in the end.

3. Oh No, the Furnace Won’t Come On

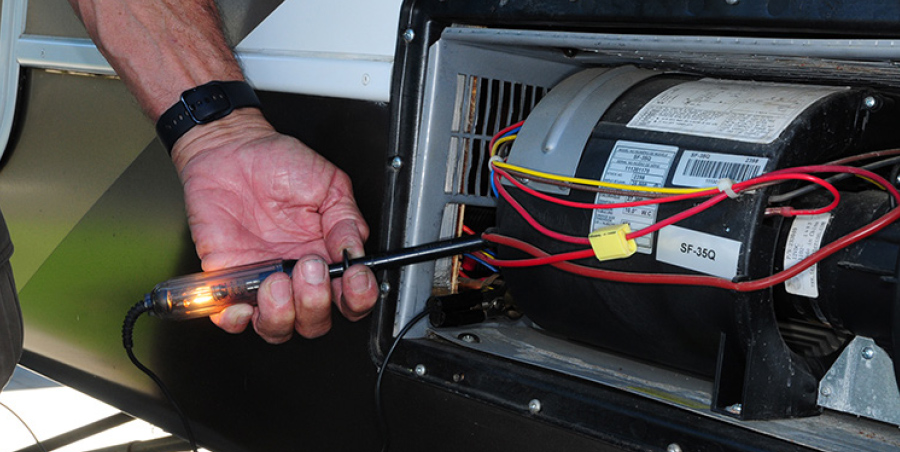

On/off switches are provided in most furnaces. While it may seem over simplified to suggest that the switch must be in the “On” position to operate, this step is overlooked more often than expected.

4. Where’s the Air?

5. Keeping the Air Flowing

Blocking the return air vent and/or heat registers is a no-no. For example, it’s not uncommon for towels or other items to fall out of drawers and/or cabinets and block the return air vent. Manufacturers require a certain amount of space (in square inches) around the return air vent and a certain number of heat registers to properly evacuate heat from the furnace.

Floor registers can collect an unbelievable amount of dirt over time — including pet hair, which can cause a serious problem by blocking the air flow through the ducting. If you have pets that shed and are concerned about the integrity of the floor registers, remove them and apply a coarse screen material that will not impede the air flow, but will keep pet hair and debris out of the ducting — and inspect/clean frequently to make sure air flow is not impeded. Some fifth wheels have a return air vent in the basement, which can be blocked unintentionally by nearby stored items. Become familiar with the return air configuration and take measures to keep the vent clear at all times. If the return air vent is located in the galley, remove it and check periodically for anything that could have been dropped out of a drawer and possibly impede air flow.

Although furnace manufactures suggest otherwise, many owners cover the intake and exhaust ports with screens available in RV supply stores. These screens must be inspected frequently and cleaned of any obstructions to prevent furnace disfunction and overheating.

Already a Subscriber? Click here for Access to the Full Issues.