Additional Support

More to the point, it becomes unsightly.

Taking preemptive measures can protect your investment, and the best way to mitigate sagging is to install a cradle support in the middle of the roller tube. Fortunately, it’s easy to do.

Dometic is a big supplier of patio awnings to the RV industry and offers an Automatic Cradle Support assembly to prevent sagging (while the fabric is stored against the sidewall) that can be installed below any brand awning that uses a roller tube to extend and retract the fabric. There are two kits available; one has a single cradle (part #930061) while the other uses dual cradles to support longer awnings (part #930065). For this project, the dual cradle kit was installed since the awning spanned nearly the entire length of the trailer and was sagging after just a few trips. Kits are available in black or silver colors; the black looks better, in my opinion. The dual cradle kit can be found on Amazon for $79.28, which is a bargain when compared to replacing a damaged roller tube and fabric. My experience with awning repairs suggests that all awnings longer than 17 feet should have a support.

There’s not much to the installation — only common hand tools are required — but you will need one or two helpers and a ladder tall enough to reach the bottom of the rolled-up awning. You will also need a long length of 2×4 or 2×6 lumber to support the awning in the middle while you’re trying to perform the install unless you’ve got somebody who can hold it up to provide access to the area when the holes are drilled. We improvised with a Pittsburgh 36-inch Ratcheting Bar Clamp/Spreader procured at Harbor Freight (harborfreight.com; $19.99) rather than chase the lumber. The clamp was wedged between the roller tube and top of the ladder that was leaned against the trailer.

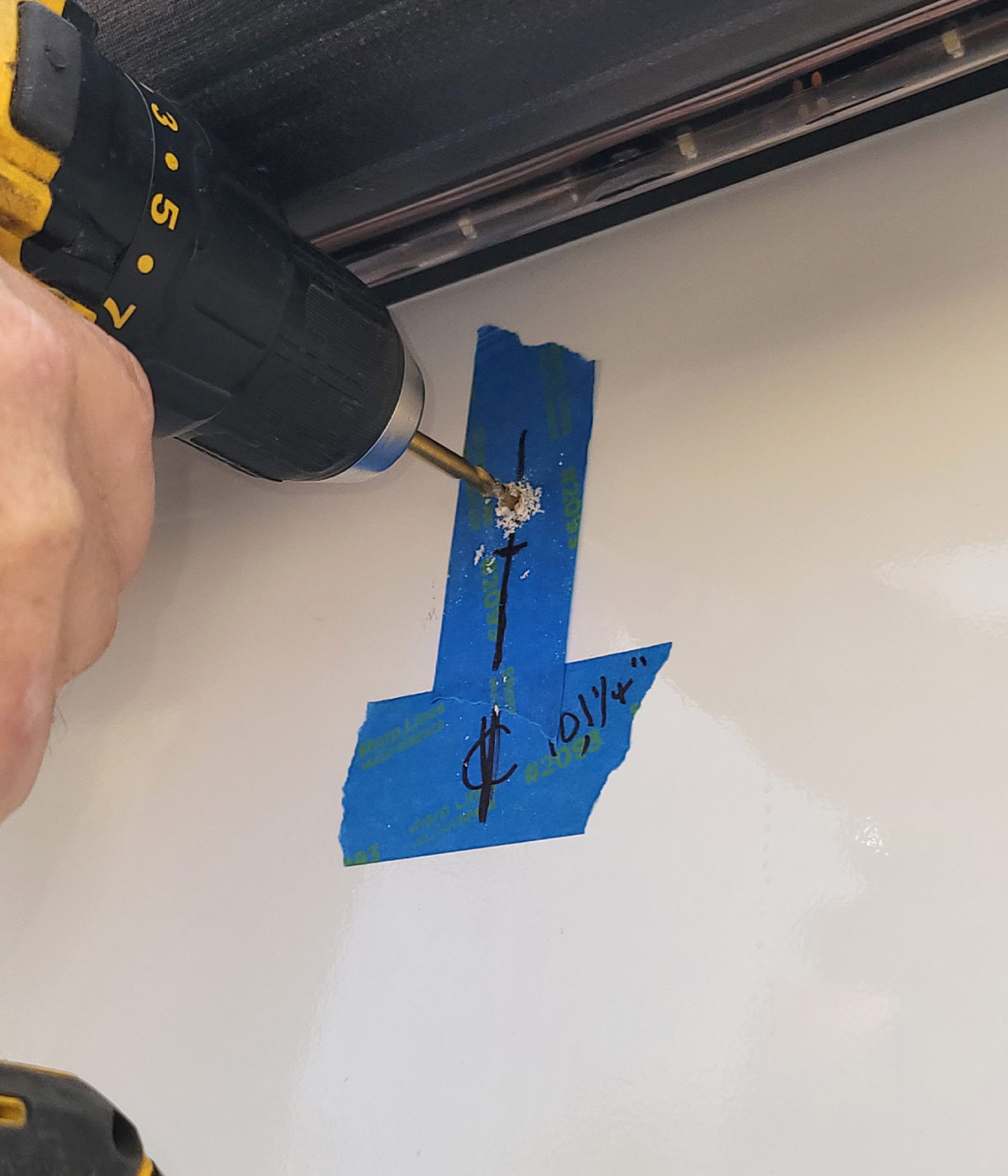

Start the installation by measuring the center of the awning roller tube. If there’s a light fixture or some other obstruction in the way, the support can be moved to either immediate side without affecting performance. Once the location was determined, painter’s tape was stuck on the sidewall on which a black felt pen was used to mark the place where the cradle assembly would be mounted — and be clearly visible.

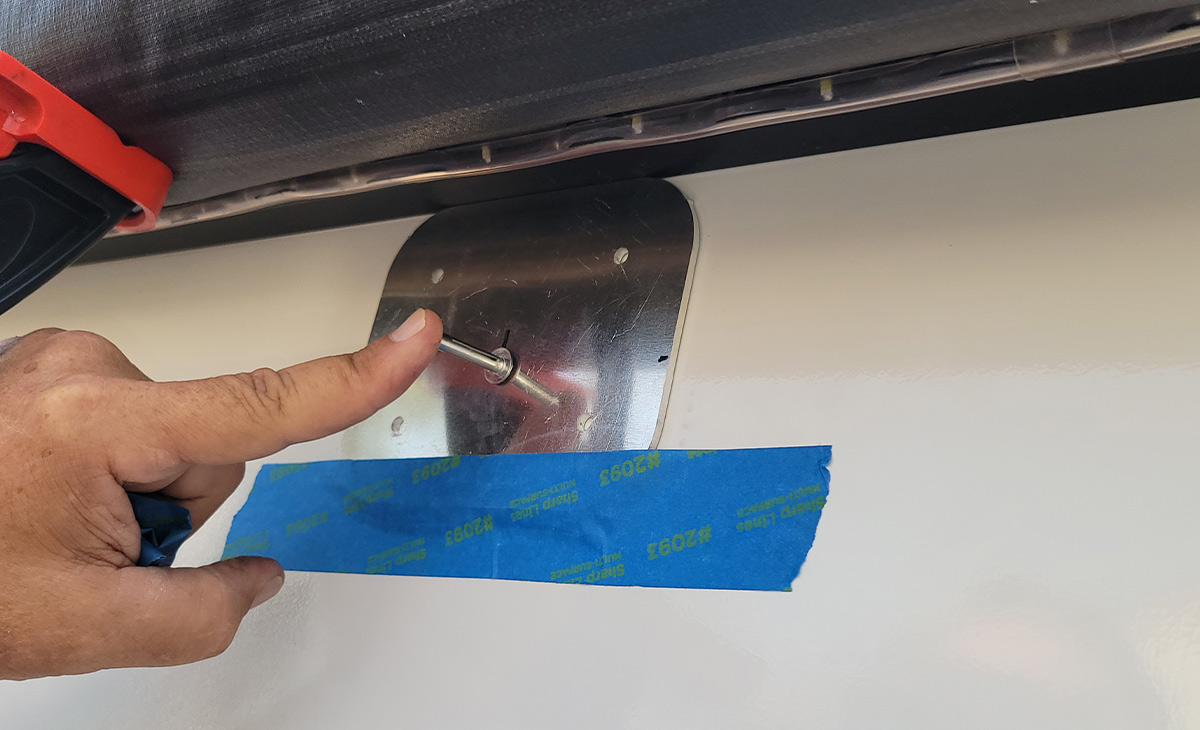

If you know there’s adequate backing at the point where the cradle assembly will be installed, it can be affixed using lag screws directly through the wall. The cradle assembly must be positioned so it has a minimum of three inches of clearance below the awning rail. If you are unsure as to any support behind the sidewall (which is probably the case), the backing plate supplied with the kit must be installed first. I found it easier to mark the position of the cradle assembly on the plate, which was predrilled while it was secured in a vice instead of trying to do it on the sidewall. The plate was then taped to the sidewall and the appropriate pilot holes for the two lag screws were drilled through the previously made holes and into the wall. Two of the rivets that came with the kit were pushed temporarily through the holes in the plate and wall. Doing so kept the plate aligned when drilling the four 3/16-inch holes for the rivets that secure the plate to the sidewall.

Silicone sealant was then pushed into the holes before installing the four rivets and again before driving the lag screws through the cradle assembly and completing the job.

Already a Subscriber? Click here for Access to the Full Issues.