Fringe Element

Big mistake.

After a few months of walking on the transition section of woven vinyl permanently adhered to the cabin floor, the binding started to wear — and just a short time later, the cloth-like material gave way entirely and presented a pretty ugly picture. To say it prematurely aged the look of the interior would be an understatement.

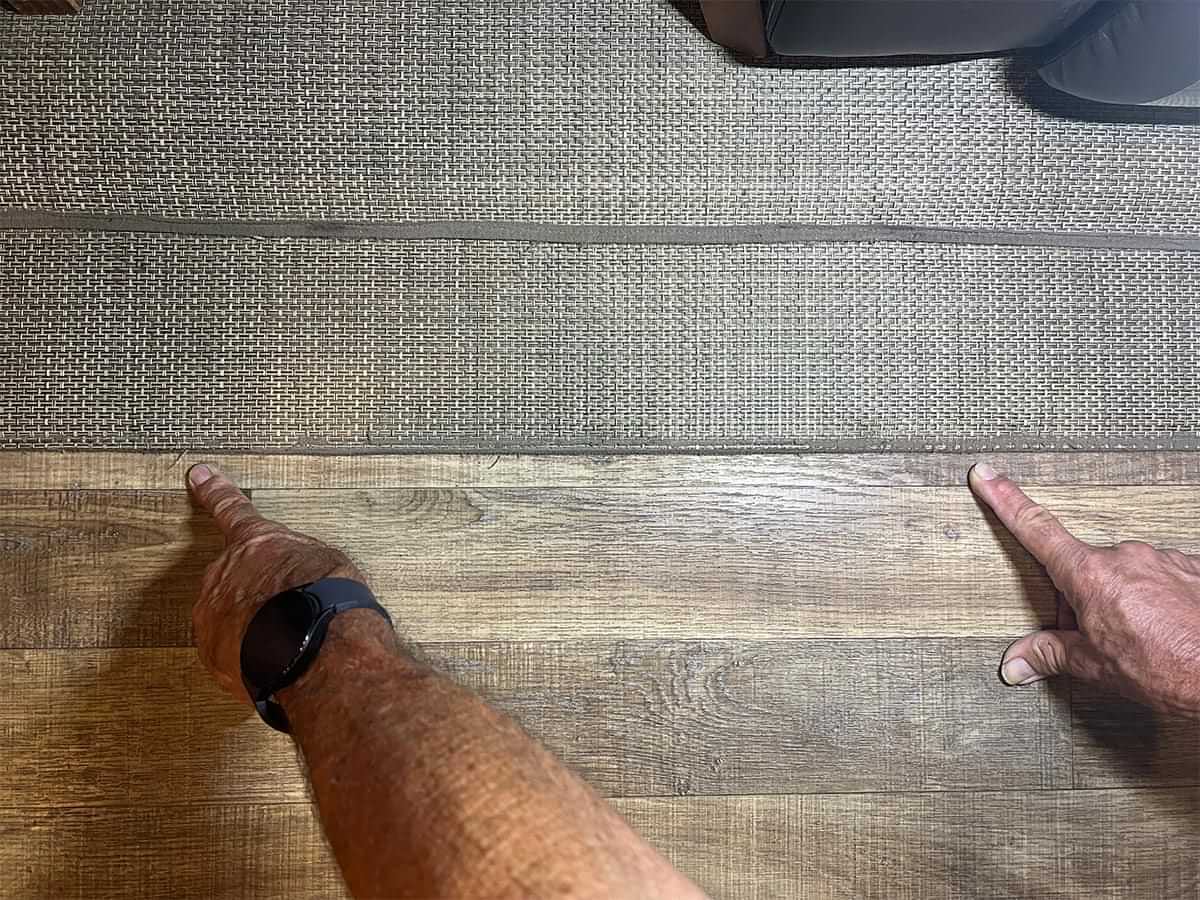

We struggled to find something that would cover the eyesore, but the search was hampered by the way in which the vinyl was applied. To allow for the slideout to glide over this section of woven vinyl, it was glued to the main floor under the slideout floor. In other words, there was no way to re-sew on new binding.

The binding that was added to the edges of the woven vinyl flooring started to wear shortly after the installation. In retrospect, adding the binding was not a good idea. Since the vinyl was glued to the main floor, it was not possible to replace the binding, which became an eyesore.

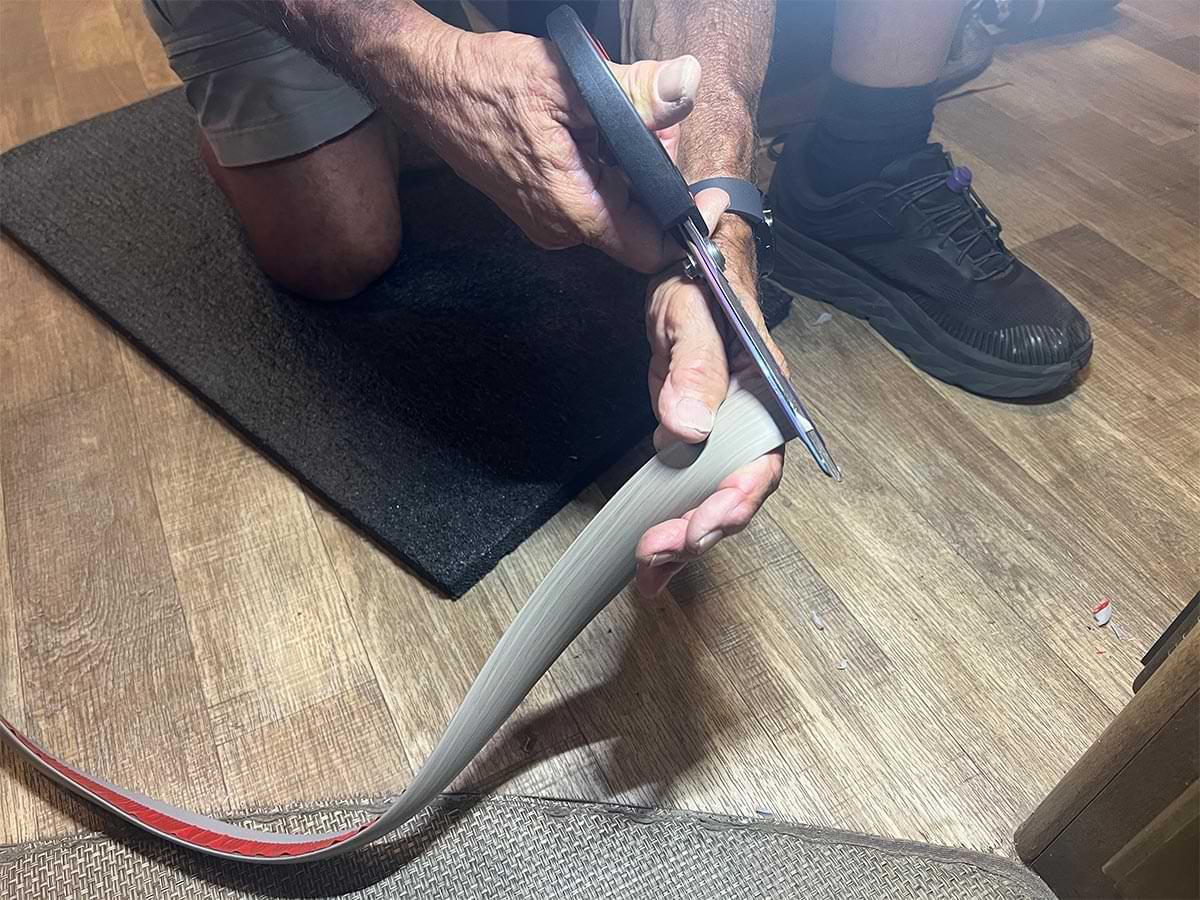

The pliability of the strip material was a big factor for this job, primarily because of the sweeping curves going into the entryway. The PVC strip is easy to bend, and a heat gun or hair dryer can be used to manipulate the material. Just be careful when using a heat gun, which can send extremely hot air and melt the transition strip.

Another benefit of the material is that it has a smooth surface and is stain-resistant, so it’s easy to clean. And, since it’s smooth (and comfortable under bare feet), there is little chance of pulling up the edges with shoes or your toes.

Before starting the project, a shorter length of transition strip was cut and temporarily installed in a central area to make sure there was enough clearance for the slideout when moving in and out and there was no restriction. Once confirmed, the coiled transition strip was unrolled on the ground outside to allow the sun to take the bends out of the material. While it was “baking” in the sun, we cleaned the woven vinyl and adjacent floor with alcohol — which is critical when applying anything with two-face tape.

We started at the entryway and cut around the end to fit against the cabinet, bending the material a little at a time to follow the curvature of the woven vinyl. Happily, this process was easier than expected and the heat gun helped keep the transition strip soft. The tape backing was released a few inches at a time, after which the strip was seated to the floor. A few more passes with the heat gun assured the PVC material would stick properly; the adhesive is very strong and has kept the transition strip in place securely for months of walking on under full-time living conditions. At first, we were worried that the seam between the two lengths of transition strip would create a problem, but that was short-lived; the two sections mated very smoothly without any lifting from the floor.

I guess the stars were aligned for this project because there are quite a few moving parts to consider when applying this type of transition strip in an RV. If you determine that this type of modification will work in your RV, you won’t be disappointed — not only does it improve the appearance of the living space, but it also looks as if it was factory-installed.

Already a Subscriber? Click here for Access to the Full Issues.