Maintaining Your Slides’ Glides

To circumvent premature failures, there’s a certain amount of maintenance that is required of the owner — including lubrication, depending on type of slideout mechanism.

One of the most common types of slideouts operates on rack-and-pinion mechanicals. It’s a tried-and-true system that has withstood many years of service. For the most part, other than lubricating the gear pack and arms with teeth cut into the steel (rack), there’s not much the end user can do. Over time, though, these systems tend to develop grunts, grinds and squeals that are annoying — and can lead to other adjustment issues. Proper lubrication will quiet down the mechanism and restore confidence that the system will keep on working as designed.

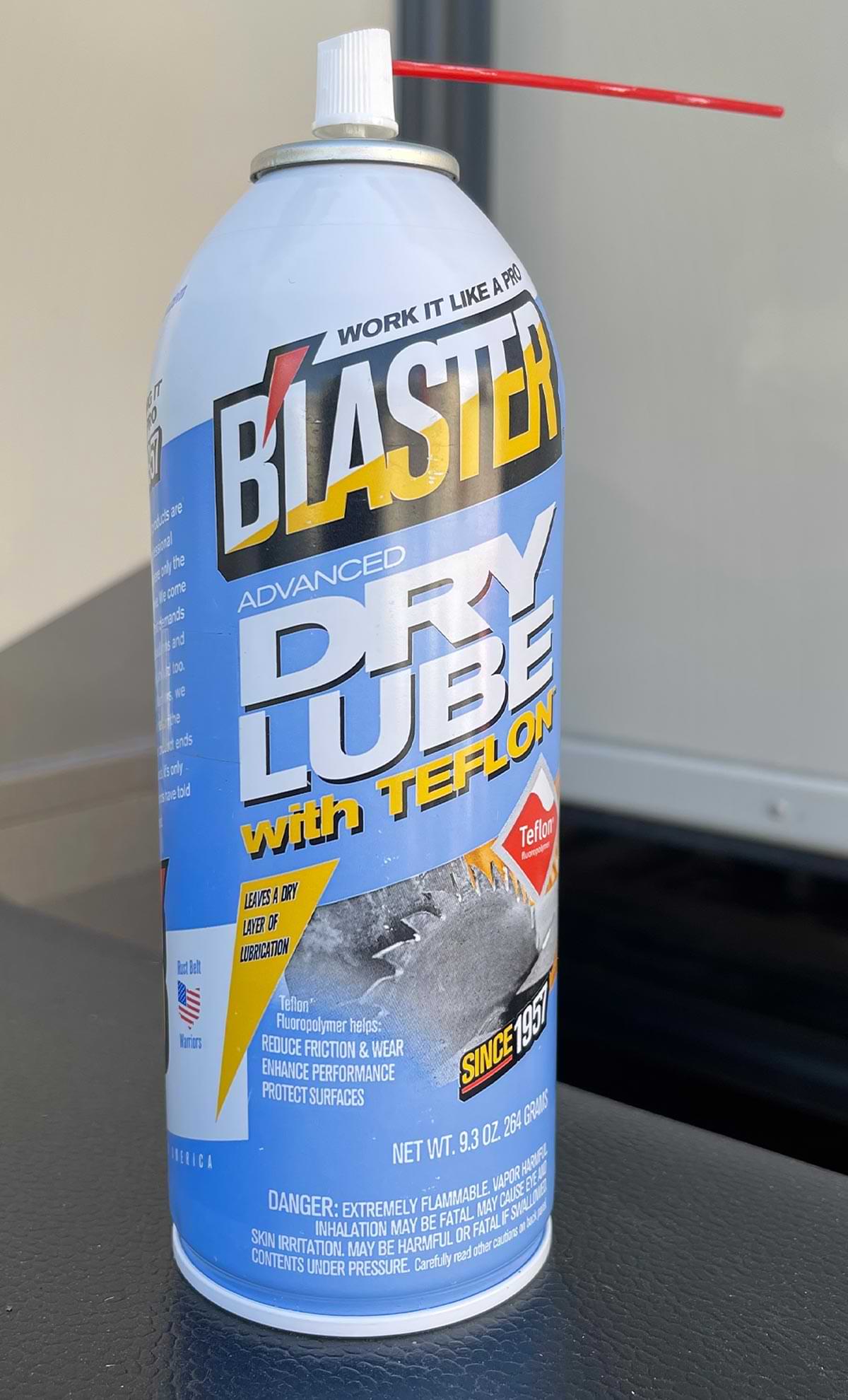

There are many lubrication products on the market, and we’ve tried most of them. You don’t want to use a lubricant that will attract dirt, which can gum up the system. One product that does the trick is CRC White Lithium Grease. This lithium-based spray is easy to dispense and will provide a uniform layer of lubrication that lasts a fairly long time, depending on the number of extend/retract cycles and exposure to the elements. Spray the gear pack liberally, but don’t overdo it. You just need enough to provide a protective layer, not one that makes mess; it’s pretty easy to visualize the lubrication coverage.

Next, spray the White Lithium Grease along the teeth of the rack — and you’re done with this part of the service.

All three of these products are available at auto parts and/or home improvement stores and online. It’s simple maintenance, with long-term benefits. Take care of your slideouts and they will take care of you.

Already a Subscriber? Click here for Access to the Full Issues.