Not So Trivial Trivets

A simple way to do this is to pick up a single floor/wall tile and add rubber legs to keep it off the counter. There are dozens of patterns out there, which makes matching — or if you desire, contrasting — your countertops fun and practical.

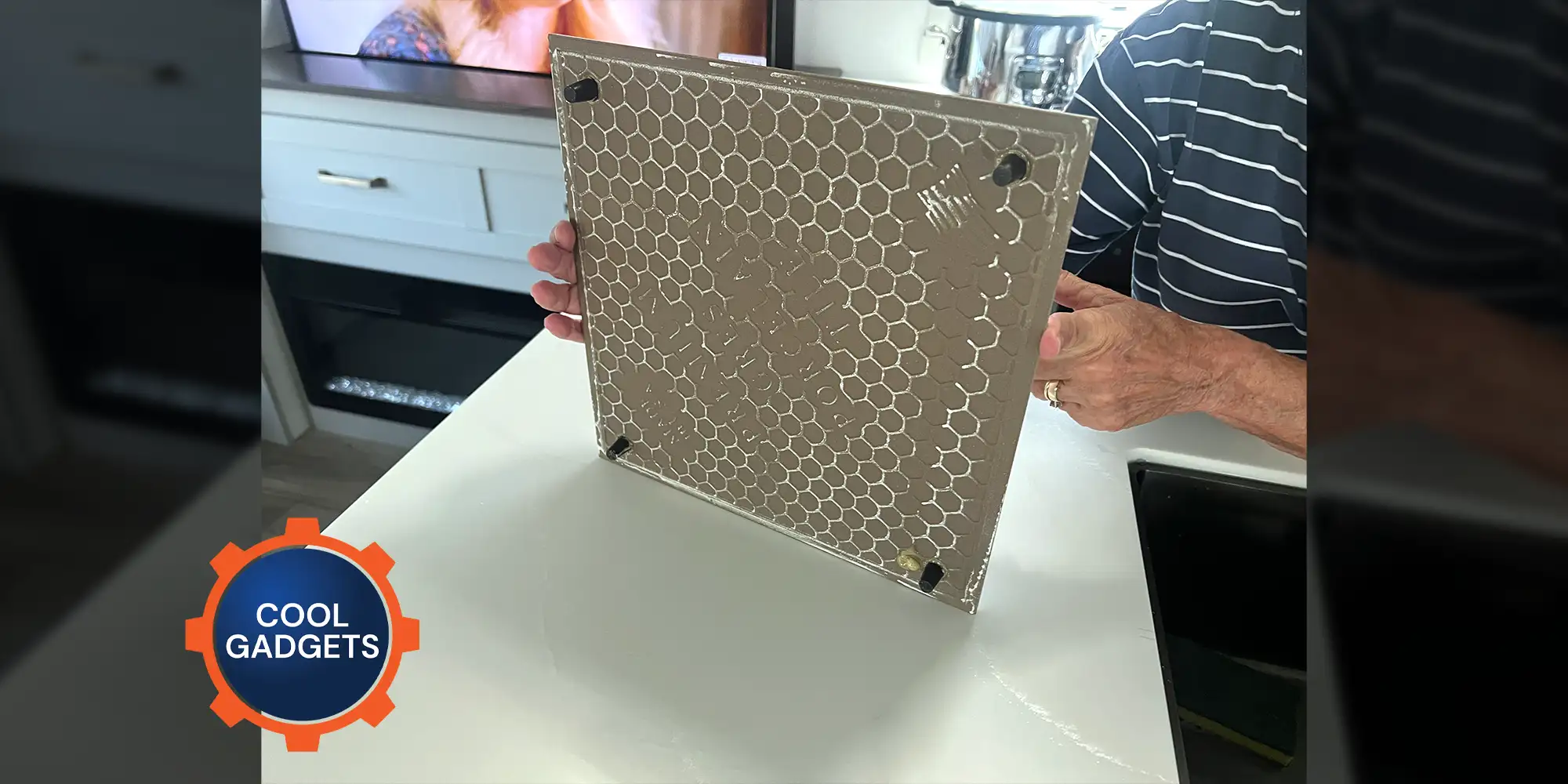

A trip to a local home improvement store landed us a 12- x 12-inch Titus Calacatta porcelain floor-and-wall tile for less than $2. This tile is actually 11 13/16 inches square, but the slightly smaller dimensions have no bearing on this project. The light color and marble-like pattern was perfect for the white-gray countertops used extensively in a friend’s new fifth wheel; the owners have used homemade trivets for years.

Rubber stoppers were used for the legs. These stoppers look like mini corks and fit nicely in the gridwork on the reverse side of the tile. Plus, they are cheap; the #000 rubber stoppers for this project cost only 94 cents for a package of two. They are just the right height and readily available in most home improvement stores on the small parts racks in the hardware aisle.

The rubber stoppers were glued on with Original Gorilla Glue, which dries super strong and is a highly versatile adhesive — except for the fact that it has a tendency to dry out in the container over a much shorter time period than expected. Just be careful not to use too much, because this glue swells up as it dries and can make a terrible mess if you adhere to the “more is better doctrine.”

These tiles are 5/16-inch thick and very durable; after all, they are designed to be walked on. They are made of glazed porcelain and the style we chose has a low sheen finish. The tiles also are abrasion resistant and impervious to water, which are necessary specs for kitchen duty.

Why go through the trouble to do this when trivets are readily accessible? Well, not only do these trivets add character to any kitchen, but they also store nicely on the countertop (can be stacked), and the space underneath the tile can be used to place other flat items. Just about all pots and pans used in an RV will fit on the tile’s surface, which prevents the heat from reaching the countertop. These trivets can also be used outside on a table — and are great conversation starters.

Already a Subscriber? Click here for Access to the Full Issues.