Power Trip

For those of us without an all-electric RV, however, ganging 120-volt AC outlets can make it difficult to operate multiple appliances at the same time. For example, in my fifth wheel, the electric supply in the kitchen and the hutch was totally inadequate. All the outlets were tied into a single 15-amp breaker, which made it difficult to run two appliances at the same time—unless power consumption was limited to maybe 700-800 watts. It didn’t take long to realize that I needed to add another circuit in the hutch area.

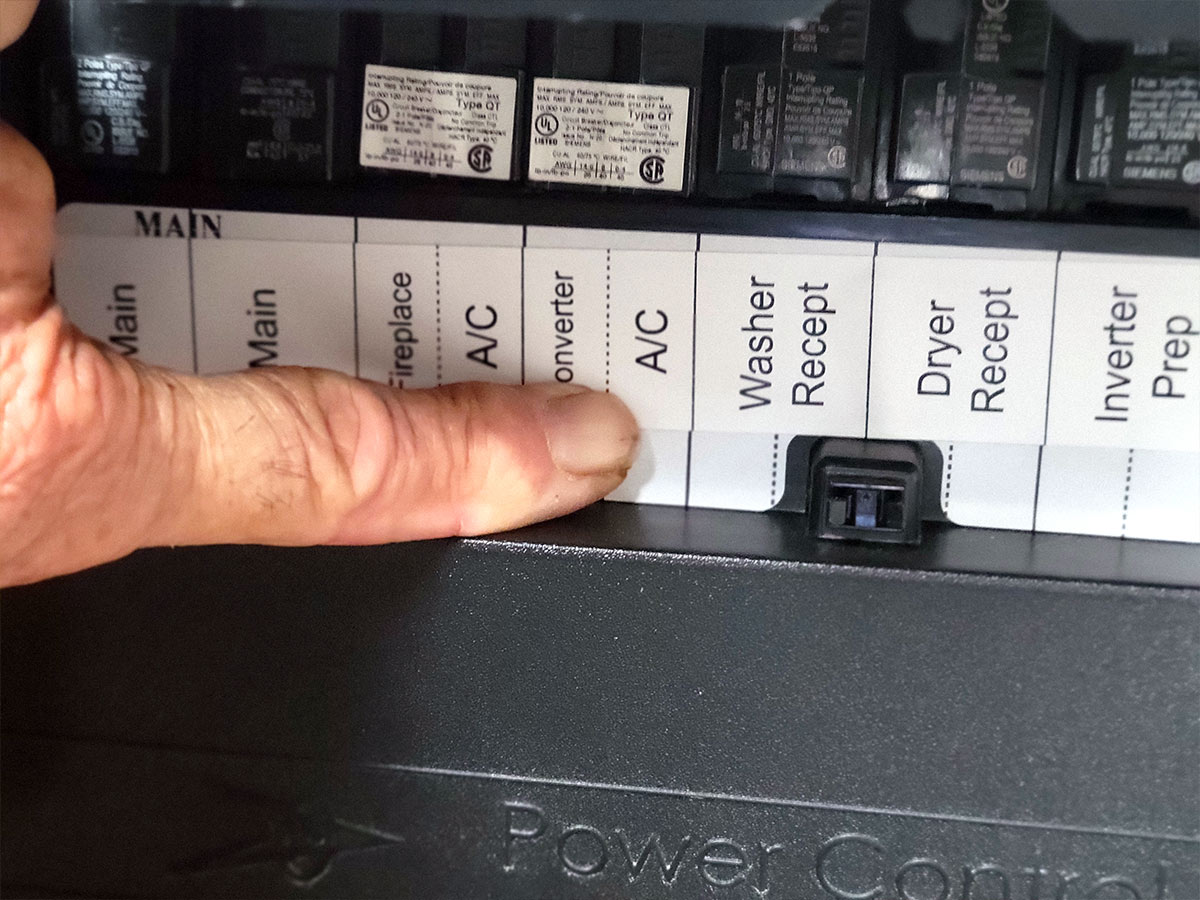

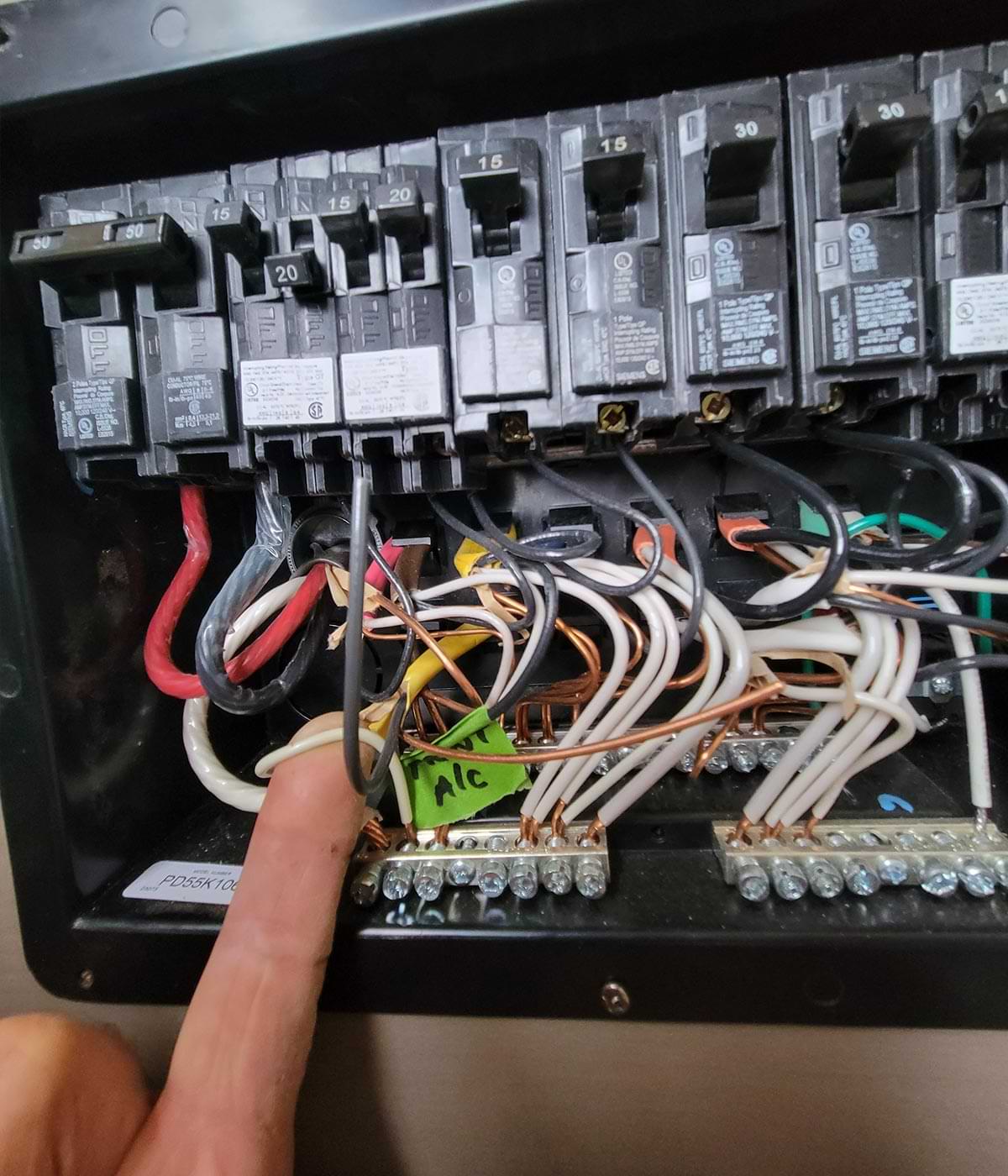

In my fifth wheel, the power distribution center was on the end of the hutch where I keep the air fryer, laptop computer and printer. Adding a 120-volt AC outlet in the wall right above the power distribution panel made the most sense, since routing the wiring was not going to be complicated. There’s no front air-conditioner in my fifth wheel (I ordered it that way to allow for a fan in the bedroom for boondocking jaunts), which made it easy to use the 20-amp circuit that was already in the panel. If the panel is filled — usually with circuits dedicated to the second air-conditioner and/or washer/dryer —you can replace one of the other breakers with a tandem-style counterpart. Tandem breakers are available at hardware and home improvement stores.

The first thing that you will need to do is disconnect the RV from electricity and make sure the inverter is off before removing the distribution panel — never perform any repairs or modifications to your RV’s electrical system without first ensuring all power is off. Then, I held the new electrical outlet plate against the wall where it was going to be mounted and made a rough outline for the cutout. A step-type drill bit was used to put holes in each corner of the markings and an oscillating-tool blade made short work of cutting a rectangle opening for the outlet. I allowed extra space beyond the markings for a little more clearance.

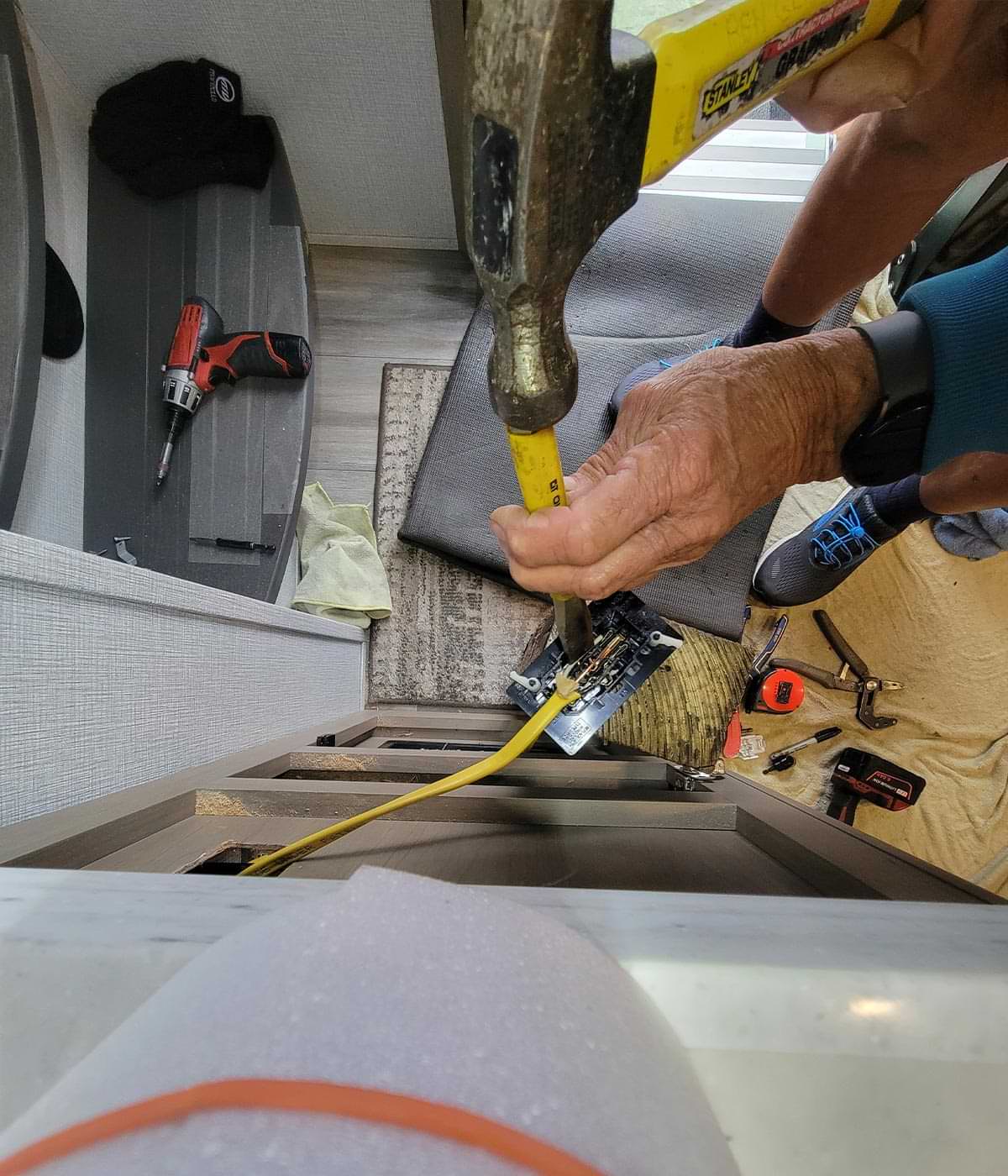

With the Romex routed, a portion of the yellow exterior casing was removed, exposing the cooper, white and black wires for connection into their designated places in the new outlet, which was tricky without the $160 tool that compresses the wires into the slots. This tool assures the wires will not come out, even on bumpy roads — but my tool was forfeited when I sold my RV repair business, so I had to improvise. I needed a solid surface where I could lay the outlet flat and try to drive the wires with a screwdriver. A 2-foot-long piece of 4 x 6 lumber fit the bill, but the wide-blade screwdriver was not capable of driving the wires into their respective slots (which are marked); if you get the white and the black reversed some appliances may not function.

Thinking outside the box, I rummaged through my tools and found a small chisel that worked. All it took was one whack of the hammer for each wire. Now it was just a matter of clamping the cover on the back; again, my makeshift lumber work top — covered with a cloth to prevent damaging the outlet — came in handy.

After double checking all of the connections, I restored power and tested the outlet for polarity. Keep in mind that this project assumes you have 50-amp service, which is the case if the RV is equipped with two air-conditioners. Now I have plenty of power to run my air fryer and microwave at the same time without overloading the circuit.

Already a Subscriber? Click here for Access to the Full Issues.