Your Nose Knows

A strong smell of LP-gas is always worrisome when you own an RV. Inside, there is a detector that will alert occupants when it’s time to vacate and diagnose the origins of the leak — but outside is a different story.

When I noticed the pungent odor apparently coming from my fifth-wheel’s right-side LP-gas compartment, immediate attention was required. There are usually two cylinders placed in opposing compartments in a fifth wheel; inside each one is a pigtail that connects a regulator to the cylinder. An automatic changeover regulator is typically in the left-side compartment, while a smaller-in-stature, pressure-reducing (30 psi) regulator is mounted in the right-side compartment. LP-gas is laced with Ethyl Mercaptan, which provides a foul odor to help detect leaks. If the smell is coming from the compartment (and your nose will let you know that when opening the compartment and taking a sniff), all the fittings must be tested for leaks.

Of course, the first thing you need to do when a leak is discovered is to turn off the LP-gas while you plan a detection strategy.

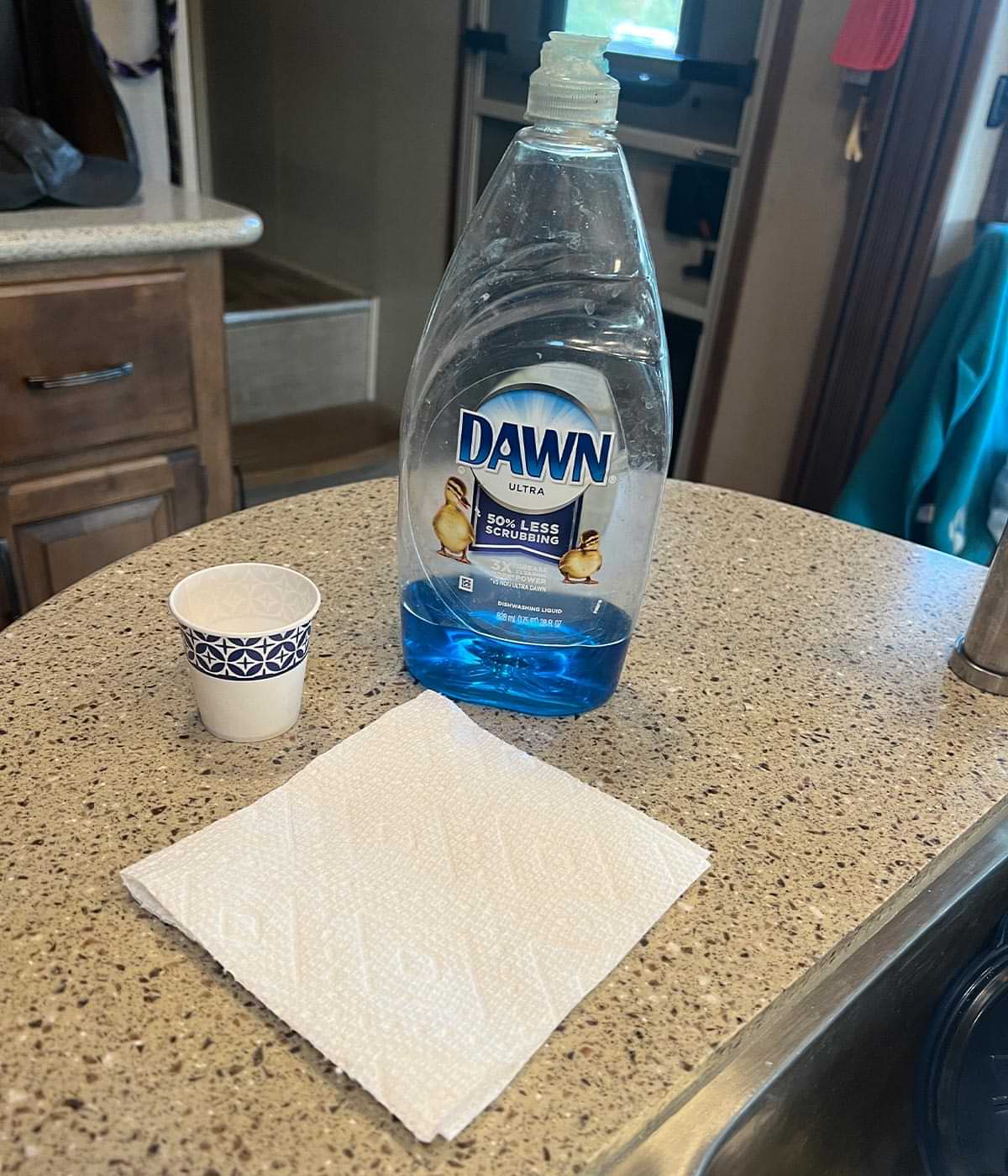

Mix the solution well and if you are not using a spray bottle, dip a paper towel or small, clean brush in the solution and apply (once the LP-gas is turned back on) the soapy water to all the connection points, including the Type 1 fitting on the LP-gas cylinder. Motorhomes have a frame-mounted tank, which does not have a Type 1 pigtail connector, but the solution is applied to all the fittings in the same manner. Take the time to also check the regulators thoroughly along with the valves on the cylinder(s)/tank.

If there is a leak, you’ll see bubbles pinpointing the location. In this case, the leak was at the hose connection point in the Type 1 fitting — and the bubbles were big.

The fix for this leak was to simply replace the pigtail. These pigtails start to become brittle over time and should be replaced every five years as part of a prudent maintenance routine. You’ll have to measure the length of the pigtail; for this repair, the one that goes into the smaller pressure regulator on the right side was the one leaking. There are two types of pigtails: One has a ¼-inch NPT fitting on the end that goes into the smaller regulator and the other is a ¼-inch inverted flare that connects to the automatic changeover regulator.

There’s not much to the pigtail replacement process, other than to make sure the LP-gas is turned off and the ¼-inch NPT fitting is wrapped with yellow Teflon tape; the inverted flare fitting is never taped. The ends do not swivel, so there must be enough clearance to turn the entire pigtail when threading into the regulator and tightening with an open-end wrench. In most cases, the cylinder will need to be removed first.

Teflon tape is not wrapped around the threads in the ¼-inch inverted flair fitting. These fittings are commonly used to connect the automatic changeover regulator to the LP-gas cylinder. Here an inverted flair elbow was added to allow for the bend needed to prevent the pigtail hose from kinking.

Most likely, the LP-gas cylinder will need to be removed to make room to connect the pigtail to the regulator. Once the new pigtail is attached to the regulator and tightened, the system should be checked again for leaks. If there are no bubbles, you’re good to go until the system can be pressure tested by a professional technician. Any time the LP-gas system is breached, it should be subjected to a pressure-drop test, which will ensure there are no leaks. This test should be performed annually, regardless of whether the system has been opened or not.

Once the new pigtail was installed, it was tested again for leaks and, with none showing, the project was done. Proper protocol is to have the system pressure tested by a professional LP-gas technician any time the system has been breached (opened). This test should be performed annually as part of your regular maintenance schedule — even if the LP-gas system has not been opened for repairs.

Pigtails are available online and at just about all RV parts stores. The pigtails for this project are from Marshall Excelsior Company, which produces high-quality LP-gas components in the USA that are protected by a five-year warranty. All trailer owners should carry extra pigtails in their spare parts’ kit so that leaks can be repaired on the spot — without interrupting a trip.

Already a Subscriber? Click here for Access to the Full Issues.