Zip It Shut

Most RV owners will tell you that Priority One is to always use caution when maneuvering their rigs over rough terrain or unknown places. The goal is to prevent impacts with tree limbs, rocks and other solid debris that goes unnoticed until too late. A vulnerable area is the belly pan, made of flexible material like Coroplast that can be easily cut or ripped from debris kicked up from the roadway or running over a tree stump, for example.

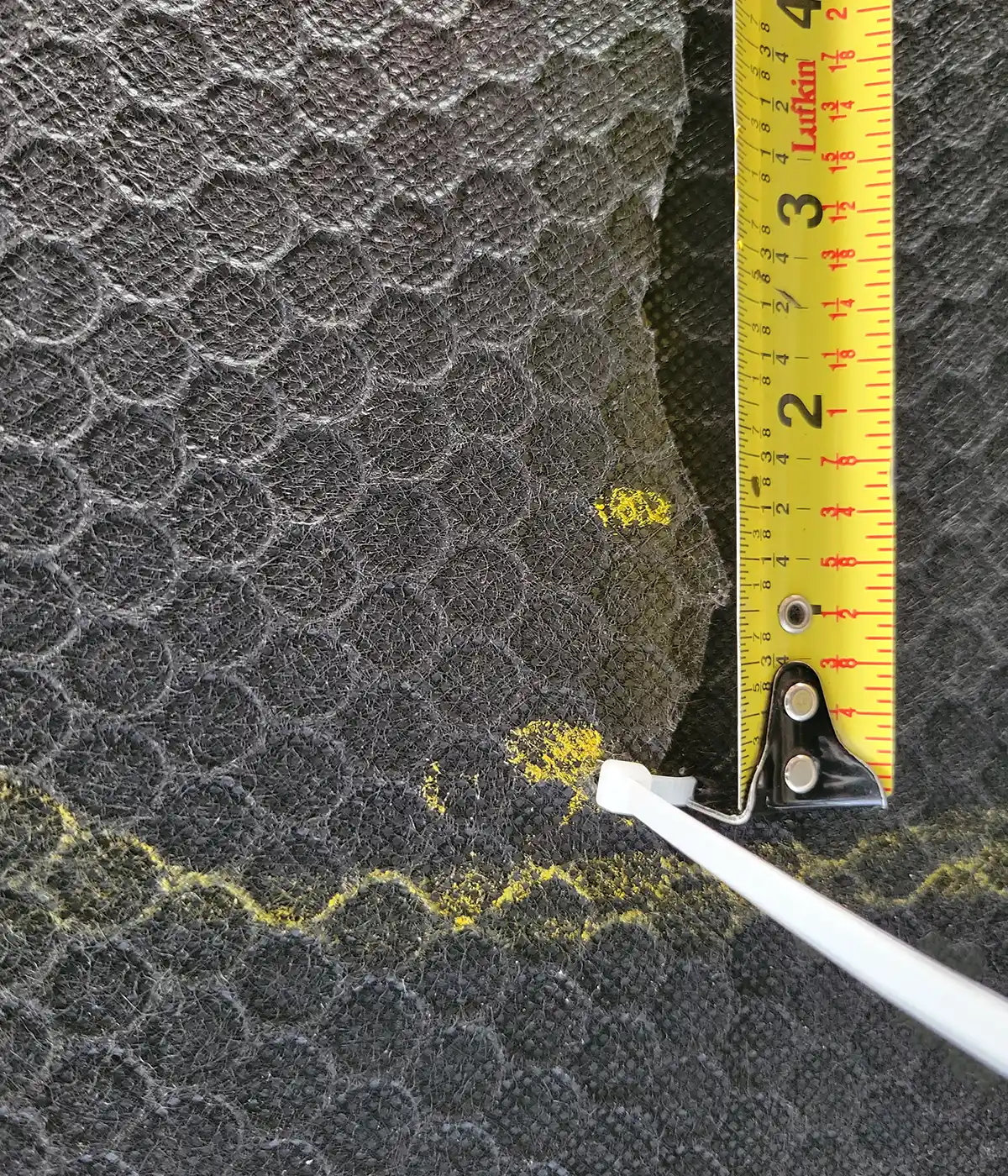

In my case, I cut a 5-inch-long section in the belly pan of my fifth wheel by mistake while working on a project.

Trying to fix that cut in the Coroplast with duct tape was futile, and sealing the cut with specialized tape for this purpose was also a no-go due to the rough surface, which was likely designed to help prevent accidental tearing. Nothing I’ve found thus far will stick solidly — for a reasonable length of time — to the underbelly material on my fifth wheel.

My next thought was to sew the cut using nylon string. The string would be plenty durable, but I could not locate a big enough needle before leaving on a trip. So, I put on my thinking cap — and came up with using common zip ties (“cable ties” for purists). They are durable, can be tightened beyond necessity for this project and they are readily available in hardware, auto parts and home-improvement stores.

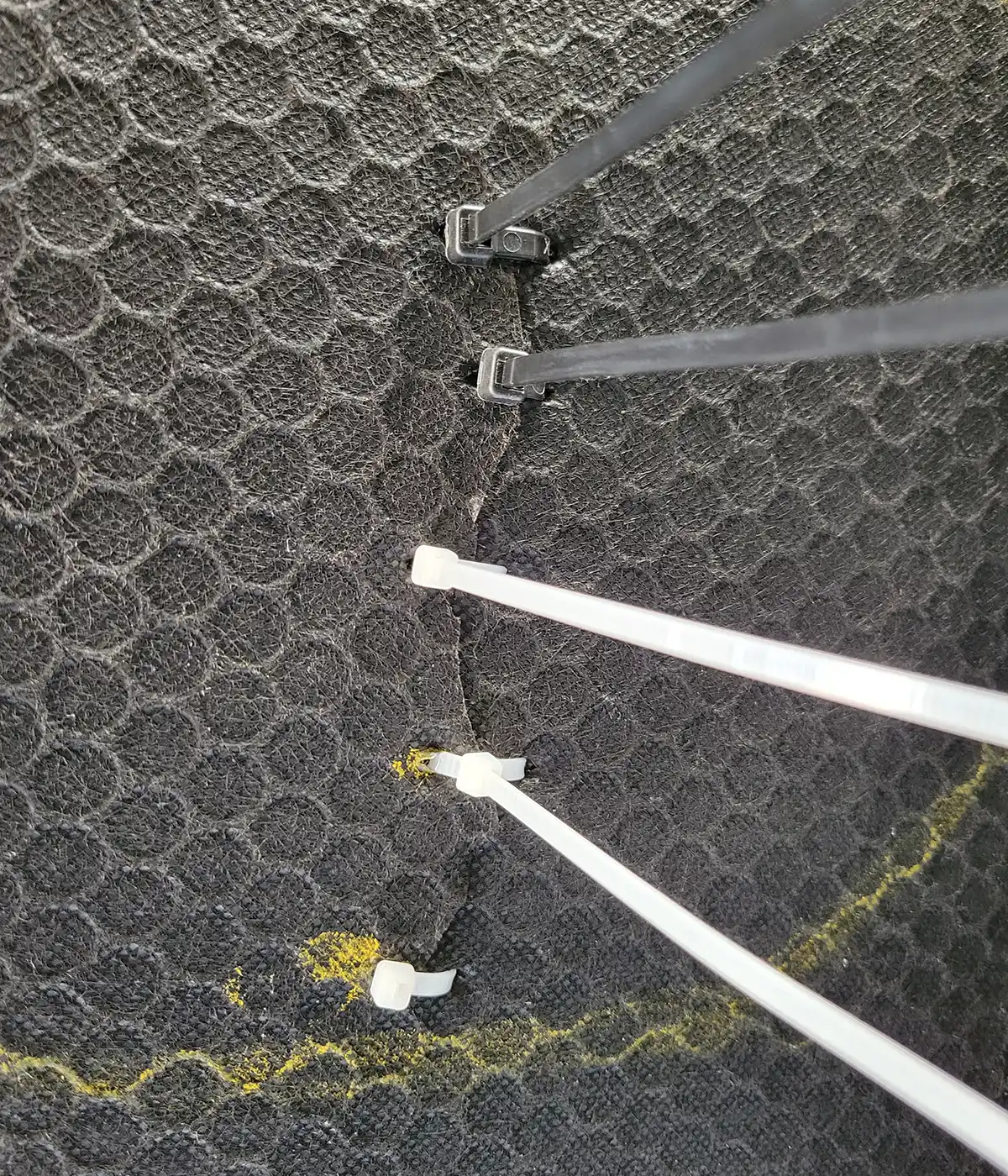

The trick is to avoid tightening the zip ties too much once they are “threaded” in place.

Since this project was all about guesswork, I estimated that covering the material at least ½-inch from the cut line and 2 inches between each “stitch” would work. At worst-case scenario, if the zip ties didn’t hold, you could install extra zip ties between the first batch.

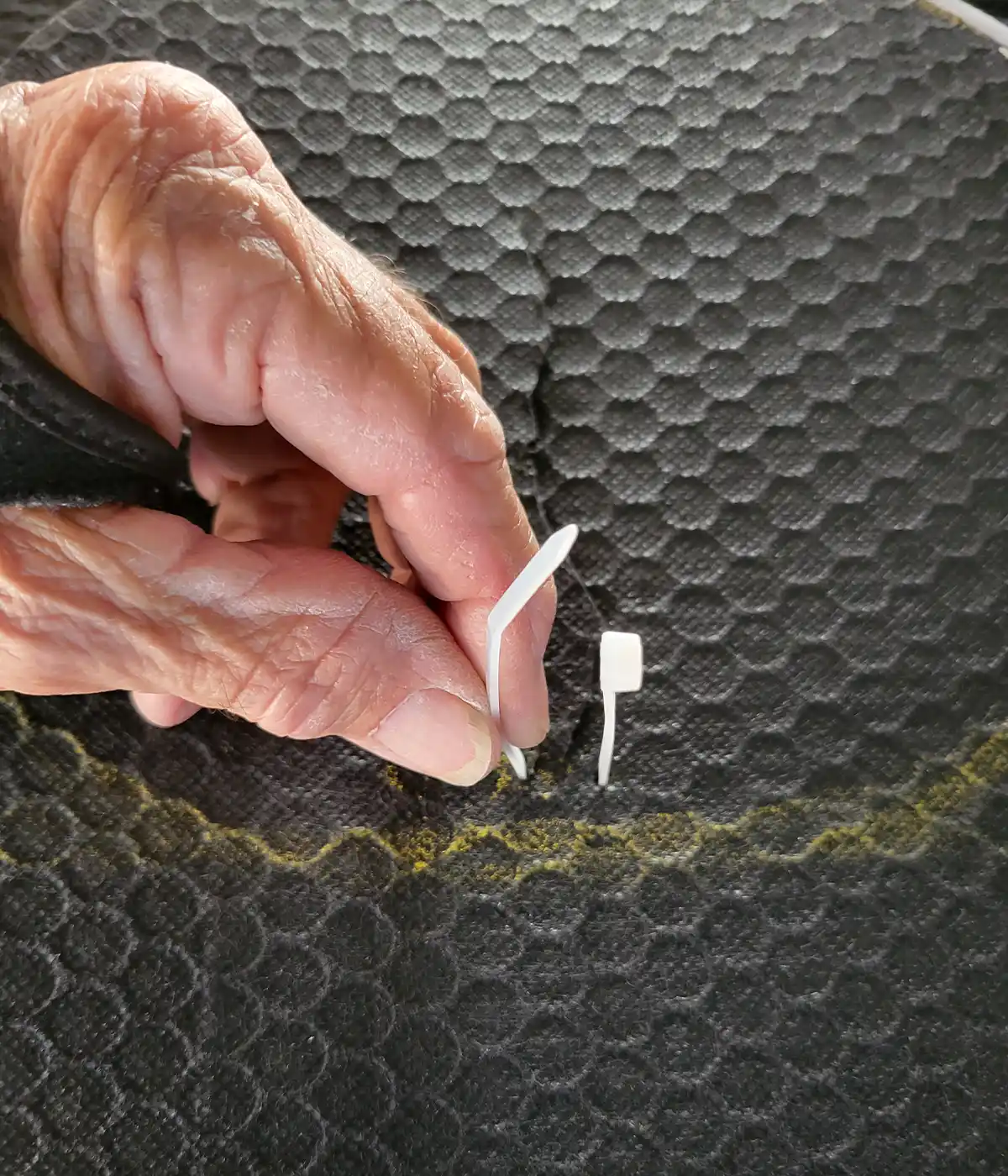

I wasn’t sure if I needed a drill bit or an awl to punch the holes through the material, so I tried both and found that a 9/64-inch drill bit worked but not as well as the awl. It was not easy pushing through the material with the drill bit as it wanted to move upward so I decided to use a very sharp-pointed awl, which punched through the material quite easily — and the tapered awl also made it possible to modify the hole just enough for the zip tie to fit tightly without binding.

I had access to either side of the cut area because I was already working on another project (installing a zippered access panel in the belly pan — watch for it in next week’s RVExpert newsletter). If you need to make a repair in the middle of the underbelly you may have to take the Coroplast loose from one side to get up in there and install the zip ties. Once the zip ties were in place, they were carefully tightened to prevent the underbelly material from being stressed and ripping around the zip ties.

Of course, depending on where the cut/tear is located, it may not be possible to use the zip ties to make the repair. If you can’t get the zip tie to feed through both holes, you can consider using a curved needle designed for sewing up skin on horses and/or cows and use some type of nylon string.

Both methods will allow you to close cuts or tears, preventing dirt and moisture intrusion — and prevent the cut from getting longer. And this quick repair process can be used in an emergency situation while on the road.

Already a Subscriber? Click here for Access to the Full Issues.