Rapid Cooling

Modifying an existing rooftop air-conditioner with a RV Airflow System’s patented foam plenum insert takes cold-air velocity to a new high — and inside temperatures to a new low.

I guess you could say that many systems really need to be redesigned. In fact, some of the newer RVs are getting away from ducted ceilings and using a direct discharge, which manufacturers claim is more efficient. For those of us with older RVs, installing the RV Airflow Systems foam changes the paradigm.

Making the Conversion

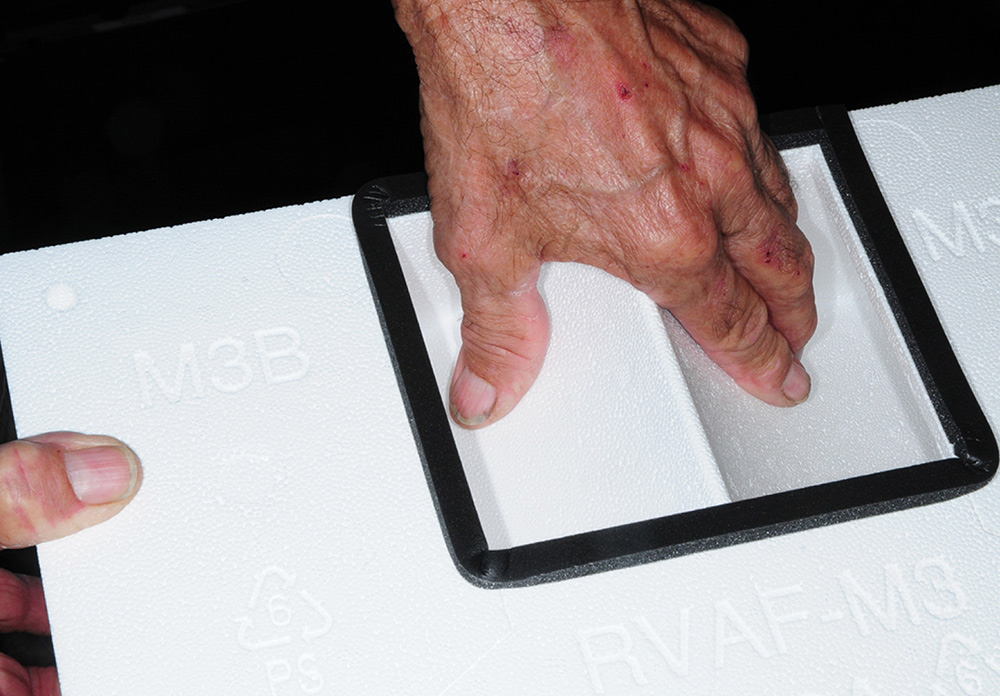

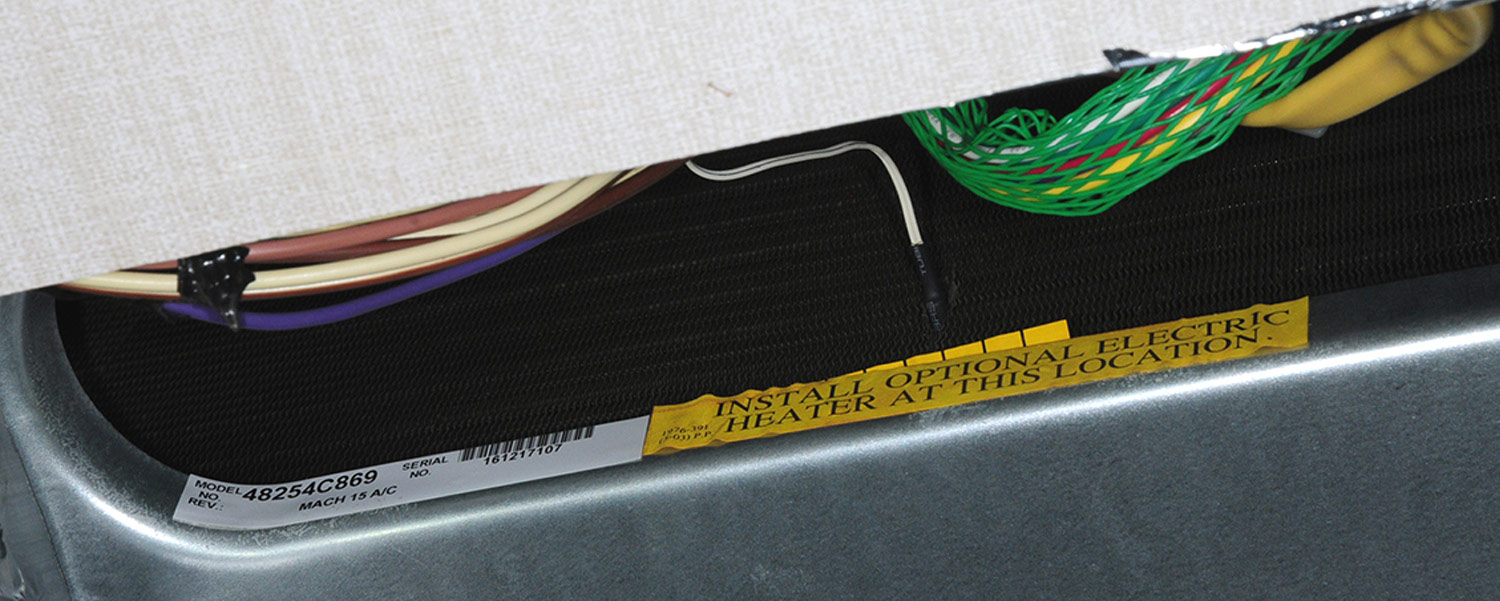

When I opened the box with the RV Airflow Systems kit, I could see that it was quite simple to install. For this project, two kits were ordered for installation in a 2017 Grand Design Solitude fifth wheel that was equipped with two Coleman Mark 8 series air-conditioners, both rated at 15,000 Btu. This 38-foot fifth wheel is located in Palm Springs, California, one of the hottest places in the United States. The RV Airflow Systems AFS foam is designed to be installed by a do-it-yourselfer and will probably take around 1 ½ hours. The instructions are easy to follow, and the company offers a comprehensive video on its website that dispels any mystery to the installation.

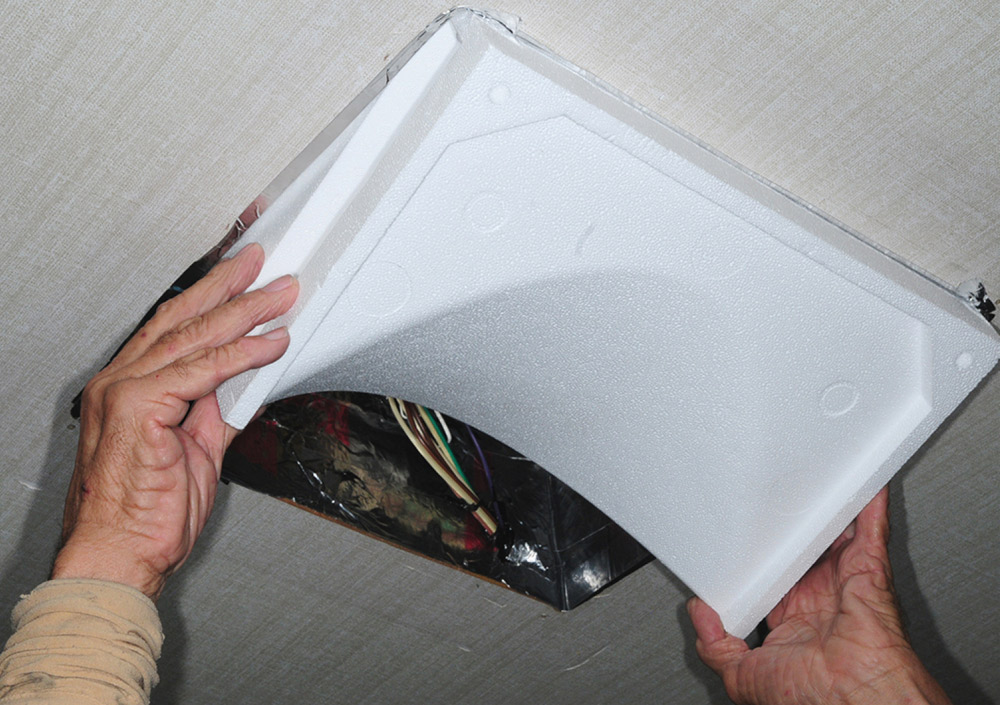

Once the ADB was dropped and the air-shower plate removed, it was noted that the divider between the return air cavity and plenum was never securely attached and air pressure had been pushed halfway into this cavity. This caused the return air to pull in part of the cold air from the plenum, creating far less efficiency. Had this fifth wheel been in a humid climate, quite a bit of frost and ice would have built up on the evaporator. The separator was discarded for this installation, so this issue was solved.

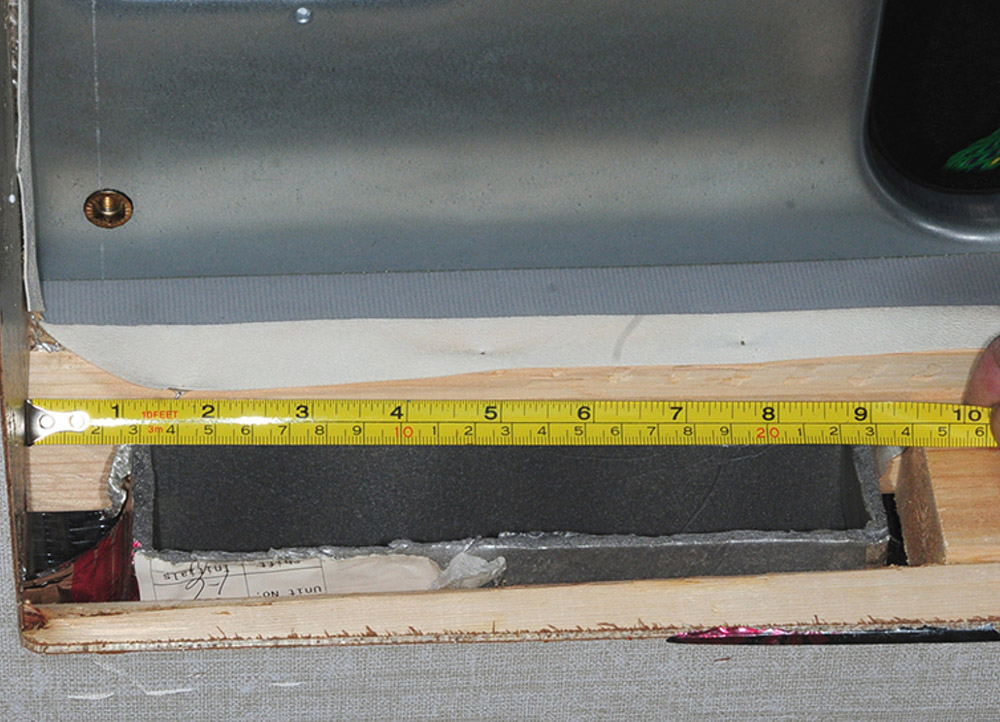

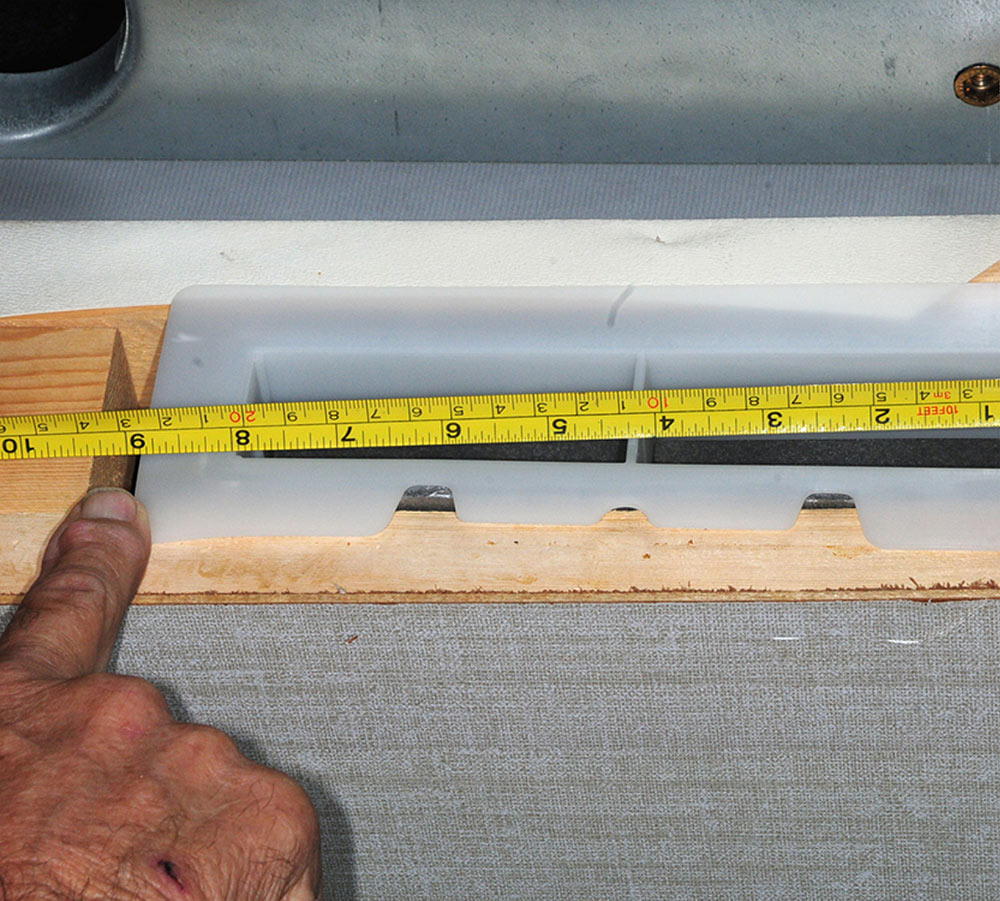

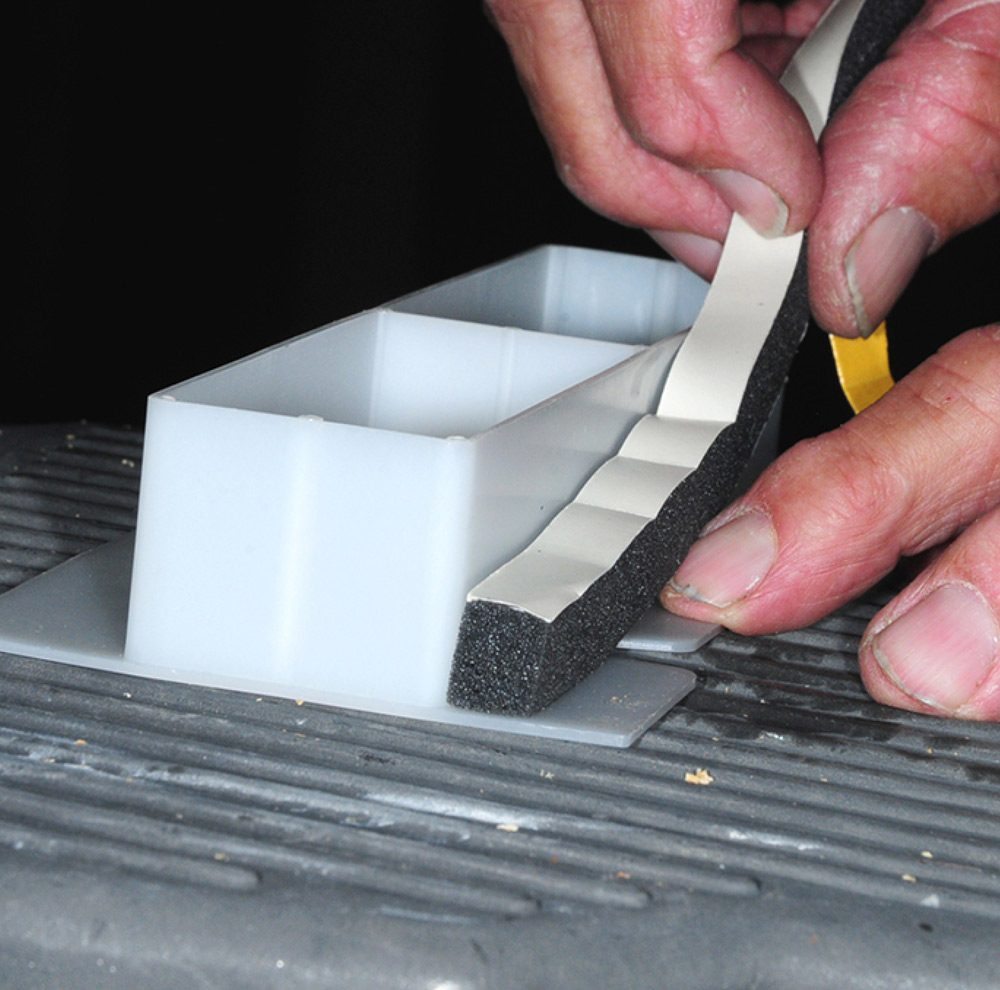

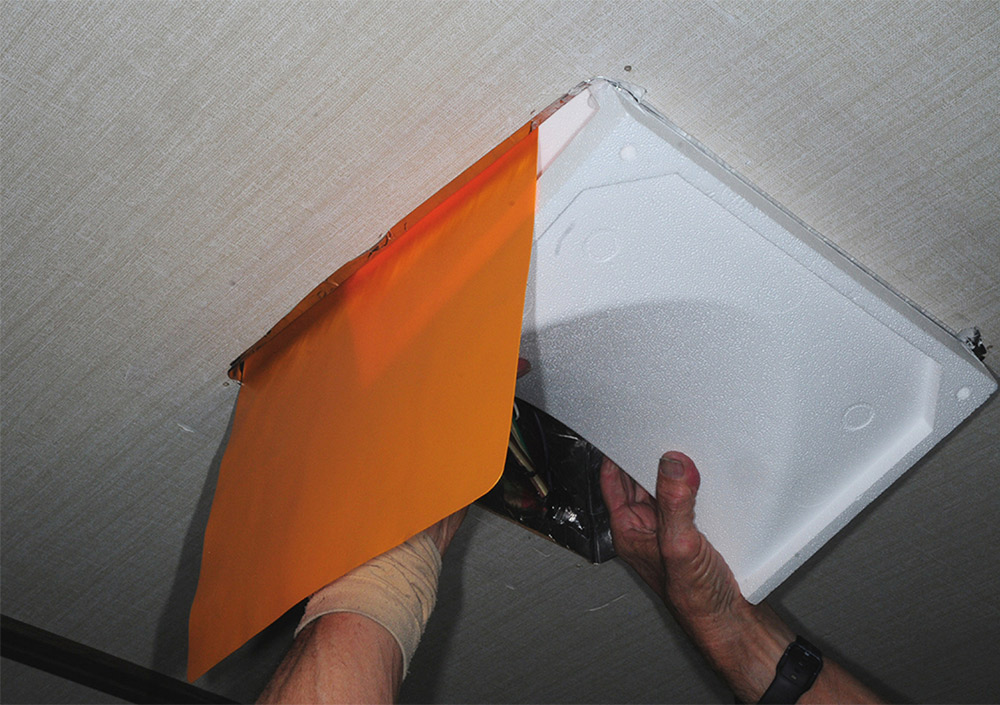

After confirming the fit, the AFS unit was removed in order to install the duct inserts; the kit comes with 1-inch duct adapters, which we needed for this project after measuring the duct opening from the top of the mounting bracket and from the top of the plenum duct. The adapters were sealed with aluminum tape on all sides. It’s possible to trim the duct adapter, if needed, with standard tin snips, making sure the sheer edge is to the rear after dry fitting. We had to make a few minor modifications because of the location of the ducting. Once that was done, the strip of foam gasket was applied around each duct insert, making sure they would be as tight as possible.

Right from the get-go it was obvious that airflow was stronger than before the installation of the AFS foam modification — and it was quieter. Both the rear and front air-conditioners were checked with a decibel meter before and after the installation. At the ADB, noise level was reduced from 83.5 to 76.3 decibels. While sitting on the recliners in the living room, the noise level went from 69 to 63 decibels. Lying in bed, the noise level from the bedroom air-conditioner was lowered from 69.4 to 68.2 decibels.

Most impressive, however, was the aforementioned increase in airflow. While the company claims improvements of 40%-50% on most conversions, we had no way to really test this other than seat-of-the-pants, but it was immediately noticeable. For an investment of $180 for each air-conditioner and a couple hours of time, the addition of the RV Airflow Systems AFS foam insert can easily substantiate the company’s claim of “it’s like having a second or third air-conditioner.”

Already a Subscriber? Click here for Access to the Full Issues.