Keeping the Air Flowing Freely

Regular air-conditioner maintenance will keep the air flowing and cool. Failure to take the time to assure proper function will lead to poor efficiency and reduced cooling.

Fortunately, the maintenance checklist is not that long and many do-it-yourselfers can do the work themselves, unless they are not comfortable on the roof of an RV. Keep the A/C clean and you can realize big hikes in performance.

In its simplest form, cleaning the return air filter(s) reaps big rewards, unless there is a component failure. Typically, all you need is a little soap and water to clean the filters. These filters are attached to the air-distribution box (ADB) and are easy to remove for washing.

Keeping the return-air filter clean also keeps most contaminants from clogging the evaporator, which over time will certainly reduce the efficiency of the air-conditioner. During heavy use the filter should be cleaned every three to seven days, depending on the climate and the amount of dust, pollen and debris that’s in the air — and that includes particles stirred up by moving rugs or towels. You’ll be amazed how much stuff is picked up from the inside of the RV, even with all the windows closed. Even cooking in a closed RV can add grease to the filter(s) and the evaporator (which is why it’s smart to always run your stove’s exhaust fan while cooking and running the air-conditioner).

Aftermarket filters offered by RV Air are designed to trap airborne contaminants and help relieve allergy symptoms for some people, and the company’s filters with activated carbon will also remove odors. RV Air filters are generally available to Coleman-Mach and Dometic air-conditioners. Owners of other brands may be able to make the generic filters work — just check with the company first. RV Air’s filters have a MERV (minimum efficiency reporting value) of 6, which will block particles larger than 3.0 microns (rated at 3.0-10 microns). A Merv 6 rating will not reduce the efficiency of your air-conditioner, but a filter with a Merv 15 rating, for example, will drastically restrict the air flow to the evaporator. The rule of thumb is that the supply air should be equal to the return air into the evaporator. Filters are also available for ceiling-mounted registers.

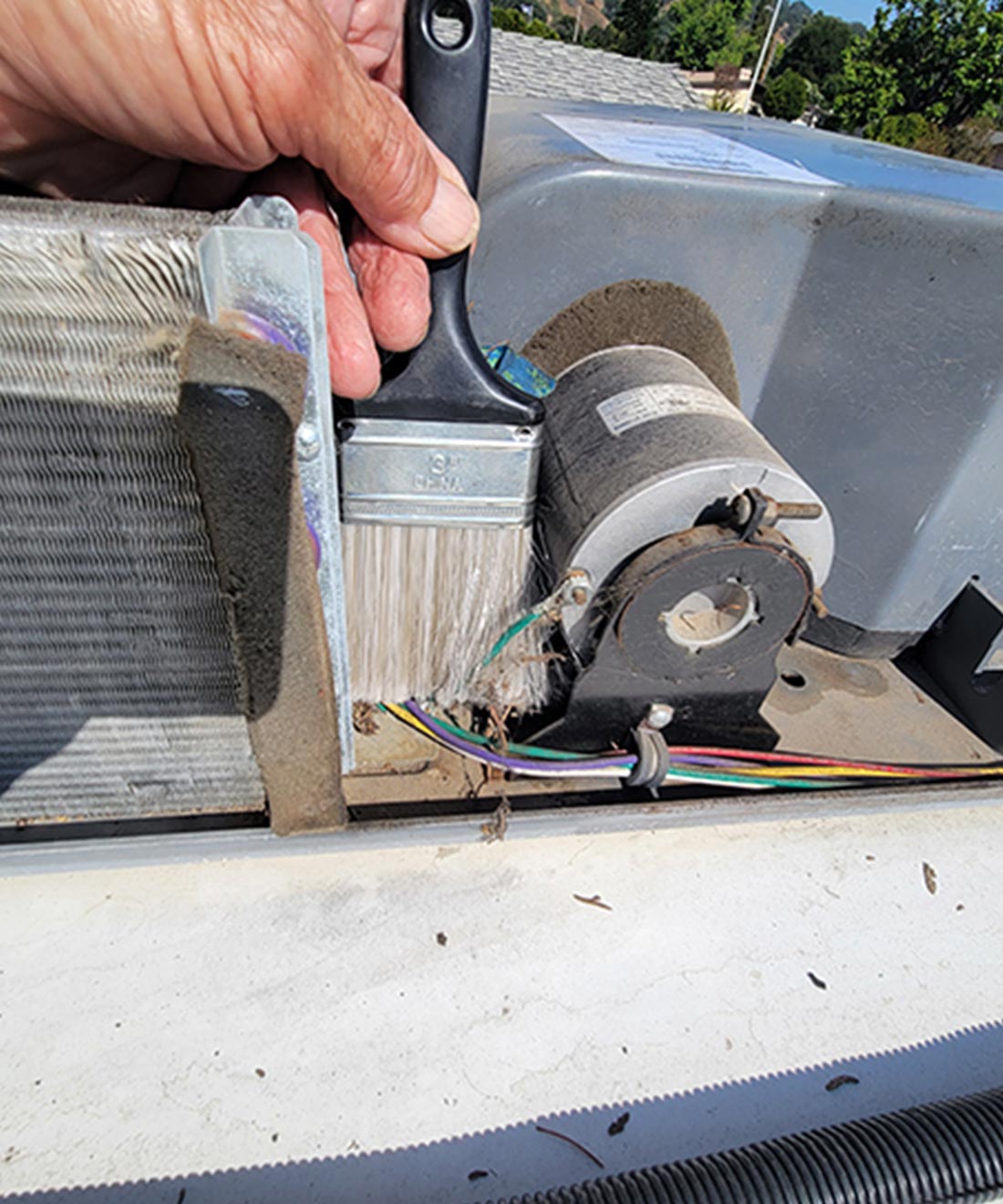

The space under the shroud can be home to critters and plenty of dirt. Don’t be shocked to see a huge network of spider webs or maybe a bunch of leaves — courtesy of parking under trees — and plenty of other debris. Start by cleaning the components carefully without detaching or damaging any wiring; compressed air (100 psi) from a nozzle can be used to blow out all the dust and debris. Be careful not to get too close to the condenser fins, however; too much air pressure can damage the fins. You may not see a lot of dust expelled from the condenser since the fan continuously blows through it, but this step still helps. Always inspect the condenser after a sandstorm or when camping under shedding trees, like cottonwoods.

I’ve seen many air-conditioners over the years where the condenser fins were completely mangled or flattened to one side, which will reduce efficiency. Straightening the fins can be painstaking, but a commercial tool for this application may speed up the process. You can also use a simple butter knife or similar tool that’s not too sharp to straighten bent fins. Once everything looks okay, reinstall the shroud and move to the inside of the RV to clean the evaporator.

The return-air filter is removed from the access panel and washed in the sink with soap and water. Make sure it is dry before reinstalling to prevent moisture gathering in the evaporator. In dusty areas, or when the air-conditioner is run most days, this filter should be cleaned at least once a week. Remove the filter from the return-air access panel so it can be washed with soap and water in the sink.

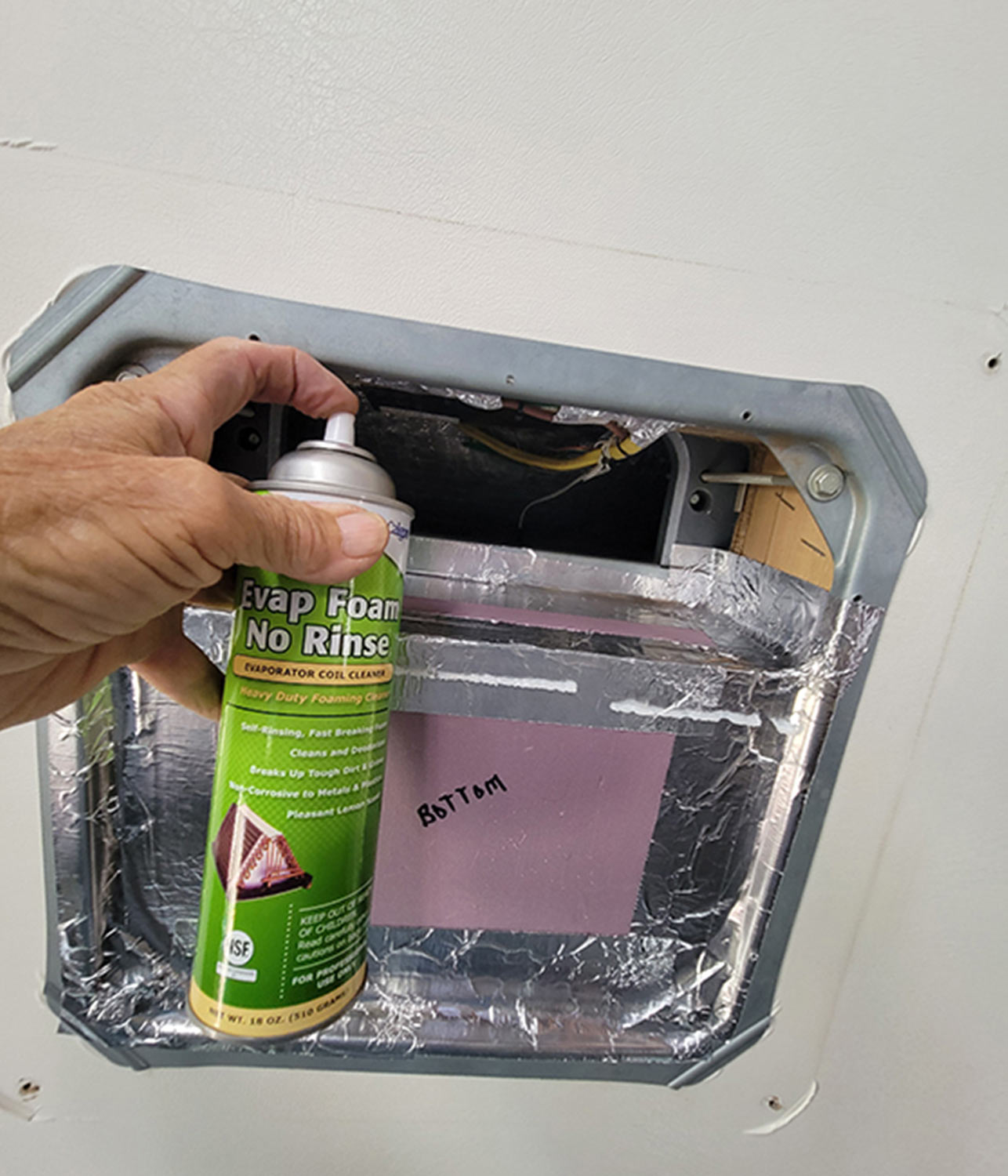

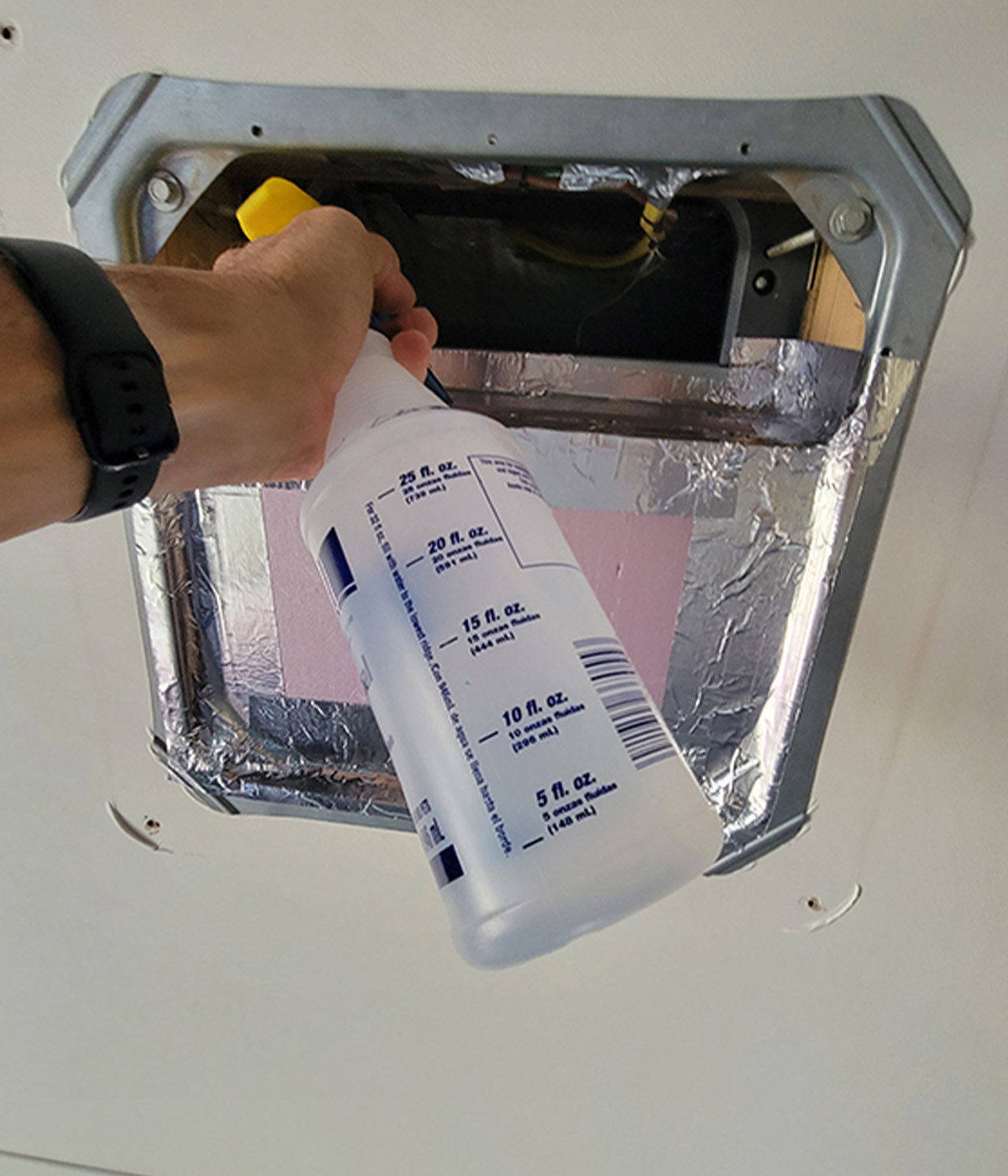

Newer formulations such as Nu-Calgon’s Evap Foam No Rinse Evaporator Coil Cleaner are self-rinsing; if you use an older formulation, be sure to rinse it thoroughly (all residue is gone) with a spray bottle filled with water. The water and cleaner will exit through the drain and down the side or back of the RV.

Next, you will need compressed air. Look up into the plenum cavity and you’ll see the fan; it may or may not be covered in dirt and dust. Don safety glasses and blow the compressed air on the “squirrel cage” or fan, dislodging any dust and/or debris. (A buildup here can actually cause the fan to be out of balance.) Inspect all the wiring, which includes the 120-volt AC Romex wires, thermostat and/or furnace control wires and the temperature sensors. Make sure that everything is intact; now would be a good time to clean up the wiring, if necessary, using cable ties or other restraining method. In many cases, builders leave everything loosely hanging around up in there.

Inspect the ducting inlet if you have ceiling-mounted registers and make sure that the separator — the piece of material between the plenum and the return air — is intact. If the separator is not sealed, cold air will be sucked right into the return air making the A/C far less efficient. In any case, as the air-conditioner ages, it’s probably going to be a little less efficient. You might think about upgrading the system with an RV Airflow kit that can improve efficiency by 30% to 40% (see “Rapid Cooling” in the April 2023 issue of RV Enthusiast — magazine). It’s fairly easy to install and a big benefit is a sizable decrease in noise. The kit directs the air through the plenum directly into the ducting, eliminating cavitating and swirling inside of a cavity.

A Few Final Thoughts

Another key to efficiency is to make sure that all the ducted ceiling registers are open. Closing off several of them will put pressure back into the plenum, causing more cavitation of the air that’s forced into the ducting. If you need to close some of the ceiling registers for one reason or another, you can open the air dump at the bottom of the ADB (if so equipped) slightly to alleviate some of the pressure.

Because the air-conditioner is a sealed unit, the freon is not replaceable; there’s no port to install the freon nor do these units use a receiver dryer, which is necessary for recharging. Over the years, I’ve talked to air-conditioner technicians who have installed a port in their system and recharged it — only to find out it’s leaked again.

All air-conditioners have a start- and run-capacitor and most modern air-conditioners have a control board. Any diagnosing and/or repair of the electrical system should only be done by a qualified technician. That said, staying on top of maintenance that can be accomplished by owners will yield big benefits — and keep the sweat away in hot weather.

If the no-rinse foam is not handy, you can use Coil King Condenser Coil cleaner, which is available at home improvement stores. Clean water must be sprayed onto the evaporator or condenser to rinse off this liquid product. It must be allowed to dry before running the air-conditioner.

When it Rains, Does it Pour – Inside?

There are two different size air-conditioner gaskets — one is 14 x 14 inches and the other is 14 x 16 inches — so you will need to measure before ordering the gasket. Be sure to get a high-quality gasket so it will last a long time and not continue to compress as the weight of the air-conditioner bears down on it over time. Remove the ADB to expose the four bolts that keep the upper unit of the air-conditioner tight to the roof. You will need to scrape the gasket from the upper unit; don’t be afraid to set the air-conditioner on its side for a short period of time to gain access (it’s not going to affect the freon). Using a sharp putty knife, scrape the gasket from the air-conditioner and clean the area with alcohol to make sure there’s no oil on the surface. Then, peel the self-stick paper from the new gasket and press it into place.

The general rule of thumb is to tighten to 25-30 in.-lb., or about a ¼-inch of gasket compression. This relates to about five or six rotations of a wrench. After the initial installation, double-check the torque and/or the compression of the gasket after one or two trips on the road.

If for some reason you do have to pull the upper unit from the roof for maintenance or for repair when re-installing, you will need to compress the gasket about another ¼-inch from the thickness of the gasket at that time.

Already a Subscriber? Click here for Access to the Full Issues.